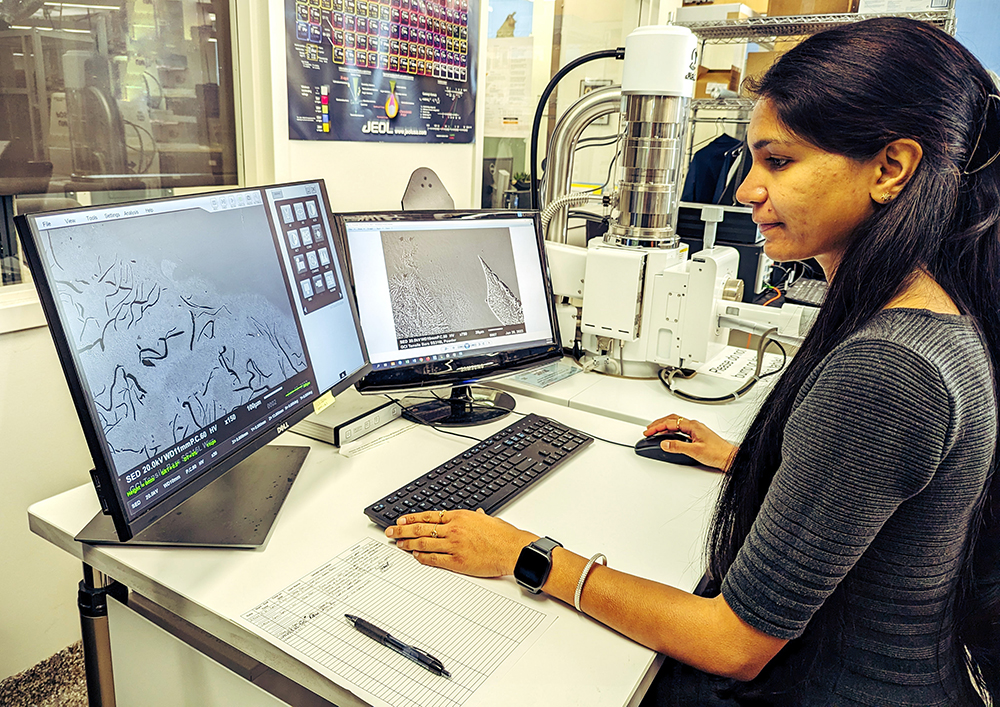

Khushbu Zope: Quantifying Heat Transfer

Khushbu is a Ph.D. candidate in Mechanical and Industrial Engineering at RIT specializing in simulating heat transfer during molten metal jetting (MMJ). “I am predicting how 3D printed metal parts cool down and how their internal structure evolves during the building process.” She develops and validates comprehensive thermal-microstructure models for the MMJ process using graph theory and aims to reduce experimental costs and enhance the field of metal additive manufacturing. “Expensive trial and error experiments on metal 3D printing machines can be avoided if we can successfully predict the cooling pattern, internal structure, and ultimately the strength of the part.”

Through Khushbu’s research, manufacturing companies will be able to build metal parts without expensive time and energy optimizations, aerospace and biomedical industries will have strong and, if needed, customized parts with complex geometries, and the field of metal additive manufacturing stands to gain in-depth process outcome knowledge.

Khushbu’s research is the first attempt to solve heat transfer problems on a macroscale 3D part using the MMJ process. “This will improve the manufacturing throughput for 3D printing processes. Applications of 3D printed metal parts will be expanded drastically.”

Khushbu's research interests also extend to formulating functional inks for printing and modeling using the aerosol jetting process. With a visionary approach and interdisciplinary mindset, she hopes her work has the potential to “revolutionize the manufacturing industry by advancing technology and enabling the efficient production of functional parts through additive processes.”

The multidisciplinary nature of this project is exciting for me-- to be able to solve this problem by using knowledge from different fields like thermodynamics, 3D printing, material sciences, simulations/modeling, and programming.