Integrated Gear Design

Integrated Gear Design

- RIT/

- Gear Research Laboratory/

- Integrated Gear Design

IGD – Integrated Gear Design –

is a powerful and comprehensive computer program for gear design, analysis, optimization and troubleshooting of gear drives.

It integrates a virtual gear generator with algorithms for tooth contact analysis, backlash analysis, free-form design and automatic generation of finite element models for stress analysis. IGD is the tool to be used when noise, vibration, life, or endurance are key factors to be considered for existing or new gear drives.

IGD has been developed thinking of both advanced gear design and gear manufacturing. The virtual gears can be generated by virtual cutting tools mimicking the corresponding manufacturing processes. The gear models generated by IGD can be exported to main CAD/CAE computer programs in IGES, OBJ or STL graphics formats.

Version History of IGD

Released on April 16th, 2025, and it is available to download now. Go to Help -> Check for updates… to update your current installed version of IGD. This new version includes the following features and/or enhancements:

- Upgraded Eyeshot libraries to the 2025 release for improved graphics performance and compatibility.

- Fixed a unit conversion bug related to torque in the 2D finite element model of strain wave gears.

- Enabled advanced design window access for sun, planet, and ring gears in planetary gear transmissions.

- Added generation and simulation of internal bevel gear design under straight bevel gear transmissions.

- Enhanced the smart design methodology for hypoid gears.

- Added ABAQUS FLAT file format for importing FE models into ANSYS Workbench.

- Implemented CMM-based geometry generation for hypoid gears.

- Enabled export of solid models for high-reduction hypoid gears with two teeth using axial sections.

- Introduced a generalized approach to compute the transmission error (TE) function independent of the gear type.

- Resolved various bugs and applied minor enhancements to improve overall performance and usability.

Released on March 6th, 2025, this version includes the following features and/or enhancements:

- Updated flank deviation calculations from ISO 1328-1:1995 to ISO 1328-1:2013.

- Added geometry for modeling manufacturing errors in internal spur and helical gears.

- Enabled Litvin’s TCA for select gear sets with localized bearing contact.

- Improved hypoid gear visualization for cases where the number of teeth is six or fewer.

- Fixed TCA export to TIKZ when the number of pairs of TCA is 1, ensuring three separate plots for the TE function are generated.

- Resolved various issues and implemented minor enhancements to improve performance and usability.

Released on February 21th, 2025, this version includes the following features and/or enhancements:

- Implemented a new pinion geometry for high-reduction hypoid gear sets using the cyclo-cut process, incorporating a worm-shaped tooth profile.

- Developed a coupled sliced method (CSM) validation FE model.

- Fixed issues with save/load methods for freeform geometries of forged bevel gears.

- Enhanced the smart design table for high-reduction hypoid gears by improving the illustration of possible designs.

- Added "Show All" and "Clear All" buttons in the FEA results window for forged bevel gears.

- Enabled data export for contact pattern results from the Tooth Contact Analysis (TCA) module.

- Implemented Litvin’s TCA method for spherical pivoting gears.

- Added visualization of the major axis of contact ellipses in Litvin’s TCA, with options to display it on the pinion, wheel, or both.

- Addressed various issues and implemented additional minor enhancements for improved performance and usability.

Released on January 22nd, 2025, this version includes the following features and/or enhancements:

- Improved the virtual measurement of the chordal tooth thickness for spiral bevel gears.

- Implemented the generation of a customized number of nodes on the root of the freeform geometry of forged bevel gears.

- Implemented Save/Load to file of FE model of the single tooth contact stiffness validation model.

- Implemented Export/Import abaqus data of FE model of the single tooth contact stiffness validation model.

- Implemented auto import data after extraction of Abaqus data of FE model of the single tooth contact stiffness validation model.

- Fixed an issue with the gear set mesh simulation when TCAComputationWithEyeshotEntities does not find the initial contact point and the tooth number of one of the gears is odd.

- Addressed additional issues and implemented various minor enhancements.

Released on January 13th, 2025, this version includes the following features and/or enhancements:

- Introduced virtual measurement for circular and chordal tooth thickness of spiral bevel gears.

- Resolved boundary issues on active surfaces impacted by fillet radius, freeform design, and geometry comparison.

- Fixed loading issues for FE models of forged bevel gears and updated default settings.

- Improved FE models with separate contacting surfaces and fillets for enhanced postprocessing.

- Modified Python script to extract max principal stresses at middle fillets.

- Enabled exporting crown gear gentool as a solid for internal bevel gears.

- Addressed additional issues, consolidated changes for CSM validation, and implemented various minor enhancements.

Released on December 6th, 2024, this version includes the following features and/or enhancements:

- Implemented movable splitters in definition windows for hobbing, shaping, and skiving with blades (Type II).

- Implemented python integration to extract results from .odb files from ABAQUS for selected gear types and geometries.

- Added XYZ geometry for internal bevel gears.

- Improved the definition window of forged bevel gears. Added access to tooth profile modification parameters.

- Implemented automatic generation of FE models with 3, 5, 7 or 9 pairs of teeth for forged bevel gears with or without webs.

- Implemented load/save projects of forged bevel gears.

- Improved method of generation by a hob or grinding worm to show gear tooth twist. Improved robustness of the generation method.

- Implemented other small changes and overall improvements to the program.

Released on November 15th, 2024, this version includes the following features and/or enhancements:

- Introduced movable splitters in new definition windows for hobbing, shaping, and skiving with blades (Type II), resolving issues when graphic scaling is set above 100%.

- Implemented other small changes and overall improvements to the program.

Released on November 5th, 2024, this version includes the following features and/or enhancements:

- Enhanced the definition window for forged bevel gears, with expanded support for various tapered tooth geometries.

- Improved B-rep generation for internal spur gear geometries.

- Added FE modeling capabilities for forged bevel gears with "All TCA Positions" checkbox activated.

- Implemented other small changes and overall improvements to the program.

Released on October 22nd, 2024, this version includes the following features and/or enhancements:

- Solved bug exporting solids entities of cylindrical gears with bore diameter enabled.

- Improved generation of BREPs for forged straight bevel gears with webs.

- Implemented first working version of the FE model of forged straight bevel gears with/without webs.

- Implemented other small changes and overall improvements to the program.

Released on August 30th, 2024, this version includes the following features and/or enhancements:

- Enabled compensation of errors of alignment for the standard geometry of internal gears.

- Redesigned the freeform design window for forged straight bevel gears.

- Implemented the geometry and TCA of internal bevel gears.

- Implemented fillet generation in the 3D-models of forged straight bevel gears.

- Implemented other small changes and overall improvements to the program.

Released on June 10th, 2024, this version includes the following features and/or enhancements:

- Updated the Eyeshot libraries from version 2023 to version 2024.

- Changed default background color in rendered view.

- Enabled methods to perform TCA on geometries generated by hob with protuberance.

- Enabled access to the new design capabilities of net-shape forged bevel gears in IGD.

- Implemented other small changes and overall improvements to the program.

- Implemented new approach to design spiral bevel gears with a completing method.

- Fixed issue with the positioning of pinion and wheel when loading a project with geometries applying UMC.

- Implemented other small changes and overall improvements to the program.

- Fixed issue with the blade geometry definition with different parameters on each side.

- Improved convergency of the TCA in some cases involving spiral bevel gears with curvilinear profiles and top-rem.

- Enabled FE model with advanced rim.

- Fixed issue that prevented spiral bevel geometries obtained by OPT-FIT to be added to the project treeview.

- Improved convergency of Dr. Litvin's TCA approach.

- Implemented other small changes and overall improvements to the program.

- Added geometry generated by Shaper Type II to spline couplings.

- Implemented new smart design for hypoid gears.

- Added new geometry based on ZykloPalloid process for hypoid gears.

- Implemented new geometry based on the application of Universal Motion Concept (UMC).

- Implemented other small changes and overall improvements to the program.

- Fixed error when generating a cycloidal gear reducer with the default values of the definition window.

- Made some changes to prevent issues when showing degenerated geometries of the components of a cycloidal gear reducer.

- Solved issue with the ANSYS FE model when the fillet surface is included as contacting surface.

- Implemented export 3D model for XYZData gear geometries.

- Improved solid models of internal cylindrical gears for the XYZData gear geometry.

- Improved the equation to determine the point width in face-milled hypoid gears.

- Implemented other small changes and overall improvements to the program.

- Enabled generation of a standard FE model without the definition of flanges in the shaft and the hub.

- Changed default settings of the FE mesh for spline couplings. The units for the input torque are now Nm instead of Nmm.

- Disabled export to CALCULIX for all cases. It will have to be enabled case by case upon request after checking it is implemented and works well.

- Fixed error when saving/loading coniflex geometry with barrel-shape blanks.

- Implemented other small changes and overall improvements to the program.

- Implemented load/save methods for cycloidal reducers and their finite element models.

- Improvement of geometries of bevel gears, that can now consider duplex tapered teeth as well as profile shift coefficients.

- Completed work on the computerized design and simulation of high-reduction hypoid gears.

- Implemented other small changes and overall improvements to the program.

- Implemented a new approach to define surface corrections for spur gears and helical gears as suggested by Consortium Member.

- Implemented K-Charts to visualize lower and upper boundaries of profile corrections.

- Implemented simulation of the twist of the gear tooth surface.

- Improved load/save methods for the new geometry with surface corrections.

- Implemented other small changes and overall improvements to the program.

- Enabled tooth thickness of hobbed geometry as an input parameter instead of the derived parameter as suggested by Consortium Member.

- Implemented measurement of base tangent length as an Eyeshot work unit and some minor improvements of related methods.

- Fixed bug when loading projects with computed distorted geometries.

- Enable Ball/Pin/BTL measurement for several geometries of spur and helical gears, including freeform.

- Implemented spur gear geometry generated by hob with protuberance and chamfer.

- Implemented a new approach to define surface corrections for helical gears.

- Improved the overall functionality of the definition window of the hob with protuberance and added computation of additional indirect parameters.

- Implemented load/save methods for the geometry generated by hob with protuberance.

- Implemented load/save methods for the geometry with surface corrections.

- Added functionality to measure lengths in the hob definition window.

- Implemented importing hob geometries from an Excel file acting as a database.

- Improved functionality of the Reference value for elements in the treeview.

- Implemented other small changes and overall improvements to the program.

- Implemented four types of geometry of hob with protuberance.

- Improved functionality of the definition window of the hob with protuberance.

- Implemented computation of stock left on the flank of the hobbed geometry.

- Added generation of the geometry by hob with protuberance. Enabled the possibility to choose from the hobbed-generated geometry or the finished geometry of the gear after grinding.

- Fixed exception that was thrown when generating a FE model of spline couplings.

- Implemented Load/Save methods of the spur and helical geometry for thermal distortion analysis by DANTE.

- Improved FE model for thermal distortion analysis to fix some issues with the external layer of elements under the active surfaces intersecting before intersecting the offset of the top land.

- Implemented other small changes and overall improvements to the program.

- Made some changes to the geometry of the outer rotor of gerotor pumps as requested by a consortium member

- Updated Eyeshot libraries to Version 2022.3.

- Implemented the post-processing of the distorted gear surfaces in IGD due to heat treatment after simulation with DANTE and ABAQUS. See https://dante-solutions.com/ for more information on heat treatment simulation.

- Implemented geometry and FE model for interference fit analysis of gear and shaft.

- Implemented the computation of the maximum interference or minimum clearance between the fillet surface of one gear and the trajectory of the edge of its mating gear.

- Fixed some issues with the geometry comparison of internal gears with free-form geometries.

- Various general “under the hood” improvements.

- Implemented a new FE model for distortion analysis due to heat treatment in spur gears with DANTE. See https://dante-solutions.com/ for more information on heat treatment simulation.

- Fixed issue when updating the face width of the pinion and wheel from the Smart design window of spur and helical gears.

- Improved the alignment of the TCA coordinate system in helical gears to avoid some issues with TCA in some special cases of design.

- Added the possibility to build finite element models with the whole pinion and a wheel with the same number of teeth of the pinion plus one.

- Various general “under the hood” improvements.

- Implemented new geometries of external and internal spur and helical gears with chamfered edges.

- Implemented other small changes and overall improvements to the program as suggested by the members of the consortium.

- Updated graphical IGD libraries to the latest version.

- Implemented new geometries of external and internal cylindrical gears generated by skiving.

- Implemented the comparison of profiles of skiving cutters in XYZ format.

- Added a new feature to compute and show the deviations of the profiles of cylindrical gears with respect to the reference involute profile.

- Fixed issue with TCA of helical gear drives with free-form designed tooth surfaces.

- Implemented other small changes and overall improvements of the program as suggested by the members of the consortium.

- Various general “under the hood” improvements.

- Fixed bug when importing ODB energy results.

- Implemented other small changes and overall improvements of the program as suggested by the members of the consortium.

- Fixed representation of the contact pattern in the summary of TCA of face-gear drives.

- Implemented the advanced definition of double-spur gears.

- Various “under the hood” improvements.

- Implemented tip-to-fillet interference detection as a result of TCA.

- Fixed computation of the profile shift coefficient of internal spur gears generated by a shaper.

- Fixed representation of the 2D FE model with quadratic elements for the whole gear set.

- Implemented -Export assembly- option for helical gears.

- Implemented other small changes and overall improvements to the program.

- Implemented computation of backlash in CURVIC couplings.

- Improved the TCA approach for CURVIC couplings.

- Implemented -Export assembly- for CURVIC couplings and spur gears. It allows the assembly of the gear set to be exported to main CAD computer programs.

- Removed absolute positioning errors for TCA. All gear sets now implement relative positioning errors.

- Fixed default case for hypoid and hypoloid gear drives.

- Implemented other small changes and overall improvements to the program.

- Fixed bug that prevented projects of internal helical gears generated by shaper to load correctly.

- Changed the approach of TCA for spline couplings to improve the speed of computations.

- Implemented the analysis of errors of alignment for the TCA of CURVIC couplings.

- Implemented other small changes and overall improvements to the program.

- Fixed bugs on existing features of IGD reported by the Gear Research Consortium members.

- Improved TCA and FEA of CURVIC couplings. Rotation in CCW and CW directions can be now analyzed.

- Implemented Load/Save of CURVIC couplings projects containing finite element models.

- Fixed default cases of spiral and globoidal worm gearsets.

- Implemented other small changes and overall improvements to the program.

- Implemented the geometry, TCA, and FEA of CURVIC couplings (further evaluation and testing needed).

- Fixed bugs on existing features of IGD reported by the Gear Research Consortium members.

- Implemented other small changes and general improvements.

- Fixed bugs reported by Gear Research Consortium members.

- Implemented geometry of spur gears generated by shaper.

- Implemented advanced definition of the shaper to generate external spur gears by shaping.

- Fixed some minor bugs reported or detected within the last week.

- Fixed bugs reported by the RIT's Gear Research Consortium members.

- Implemented the advanced definition windows for internal spur and helical gears generated by shaper.

- Implemented the advanced definition window for splines couplings.

- Fixed some minor bugs reported or detected within the last week.

- Updated viewport to the newest graphic library.

- Fixed bugs reported by the RIT's Gear Research Consortium members.

- Improved definition of spline couplings to allow a general definition as well as definition according to ISO 4156.

- Fixed bugs in the advanced definition window of external helical gears.

- Added highly crowned geometry for the shaft of spline couplings.

- Implemented advanced design windows for internal spur gears.

- Other small changes and improvements.

Main Features

The main features of IGD are:

- Virtual gear generator of almost any type of gearing

- Free-form design module for all types of gearing

- Compensation of errors of alignment or deflections at the design stage

- Tooth contact analysis (TCA) based on three pairs of contacting teeth

- Finite element models ready to run in main commercial FEA computer programs

- Finite element models including gears, shafts, and bearing

- Simulation of manufacturing errors and their effects on contact patterns and contact and bending stresses

- Comparison of gear geometries

- Design of flank edge coordinates.

- Backlash analysis all over the cycle of meshing

- Gear geometry export capability for additive manufacturing

- Postprocessing performance of actual gear geometries based on point clouds obtained by non-contact metrology

Gear Sets

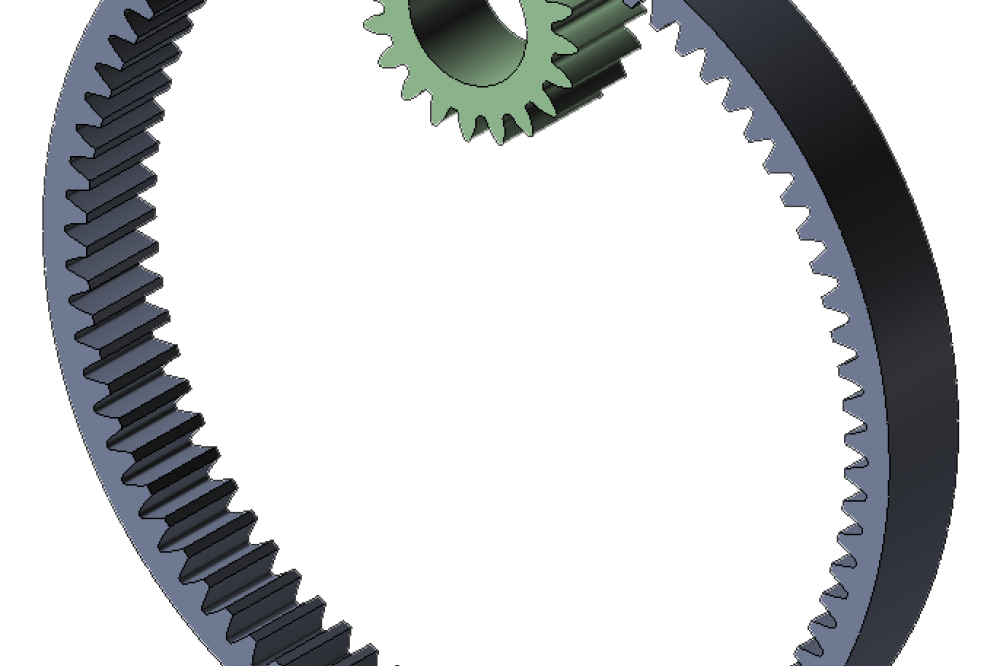

IGD has been developed considering the extension of its capabilities to all types of gear sets. The gear set types implemented in the latest version of IGD are shown on the right side figure by means of a green mark. The gear set types that are pointed by means of a red X-shaped mark will be implemented in the near future.

The gear set types are organized considering the arrangement between the gear axes into the following three categories: Parallel Axes, Intersecting Axes, Crossed Axes, and Coaxial Axes.

- Parallel Axes gear set types are organized into two groups: External and Internal.

- Parallel Axes - External gear set types include spur, helical, curvilinear, and pinion-rack gear sets.

- Parallel Axes - Internal gear set types include spur, helical gear gear sets. The strain wave gears are a work in progress now.

- Intersecting Axes gear set types include straight bevel, spiral bevel, face gear, and beveloid gear sets.

- Crossed Axes gear set types include crossed helical, offset face gears, globoidal worm and hypoid gear sets.

- Coaxial Axes gear set types include planetary gear sets and spline couplings.

Parallel axes: external

Parallel axes: internal

Intersecting axes

Crossed Axes

Coaxial Axes

Generating Tools

IGD implements a variety of generating tools for every type of gear. Straight, parabolic, or circular profiles can be considered for the generating tools, allowing tip and root reliefs to be provided in order to improve the process of tooth loading and unloading during the cycle of meshing. Root and tip reliefs are fundamental to minimize contact stresses along the cycle of meshing. The blades of the generating tools are designed considering not only the active part but also the blade edge that will generate the fillet of the gear teeth, allowing the accurate determination of fillet stresses.

Profile Types

Gear Generating Tools

Analyses

The analyses that can be carried our in IGD are arranged in two main groups:

- TCA & FEM analyses: Tooth Contact Analysis and Finite Element Modeling

- GEO-Comp analyses: Comparison of gear geometries

Tooth Contact Analysis (TCA)

Tooth Contact Analysis (TCA) involves: (i) the determination of the contact pattern and the contact path on the gear tooth surfaces, (ii) the determination of the function of unloaded transmission errors, and (iii) the determination of the function of backlash. These results are obtained considering the following user data:

- The selected pinion and wheel geometries

- The positioning errors of pinion and wheel in the gear set

- The number of pairs of contacting teeth: One or Three

- The number of contact positions along one or two cycles of meshing

- The virtual marking compound thickness for an estimation of the size of the bearing contact under light load

- The direction of pinion rotation: counterclockwise or clockwise

A general-purpose algorithm for tooth contact analysis is applied for computerized simulation of gear meshing and contact pattern estimation. It is based on a numerical method that takes into account the positional study of the tooth surfaces, which are discretized by means of a grid definition, and minimization of the distances until contact is achieved.

Examples of results that can be obtained from our TCA are shown below for a spiral bevel gear set, a planetary gear set, and a spline coupling. Application of TCA in a planetary gear set requires the determination of the contact patterns between the sun gear and each planet gear, and between each planet gear and the ring gear. A spline coupling requires just one contact position since all pairs of teeth can be simultaneously in contact.

Tooth Contact Analysis (TCA)

IGD allows the preprocessing of the finite element model of the gear set for the investigation of its mechanical behavior. Different types of finite element models are supported in IGD. Those FE models can be exported to Abaqus or Ansys for further analysis. The main features of the finite element models that can be generated in IGD are as follows:

- The user has a complete control on the number of elements to be considered on the tooth surfaces, under the tooth surfaces, and inside the rim. The nodes located on the tooth surfaces are points generated from the virtual gear generator or from the free-form design tool

- The finite element models are all set for the FE analysis at a chosen contact position or for the FE analysis along one or two cycles of meshing. The finite element models consider the direction of rotation of the pinion (counterclockwise or clockwise), and one, three, five or seven pairs of contacting teeth

- The fillet surfaces can be considered as contacting surfaces for detection of interferences

- The load is directly applied to the pinion by means of the transmitted torque while the rotation of the gear (wheel) is blocked. No assumptions of load distribution are required

- The torsional deformations of gear tooth surfaces can be considered in the finite element models

- Shaft deflections can be considered by adding the shafts to the finite element models. IGD incorporates a design tool for shafts that allows the definition of the dimensions (length and diameter) for each section of the shaft, the location of the gears, and the location of the bearings

Comparison of Gear Geometries (GEO-Comp)

GEO-Comp analyses allow the comparison of gear geometries through the determination of the distances between the corresponding gear tooth surfaces. The geometry comparison analysis requires selection of the geometries to be compared and the reference side (left or right) for comparison. One of the geometries is considered as primary geometry whereas the other one is considered as secondary geometry. The tooth surfaces of the selected geometries are brought into contact at the reference side for comparison (left or right). The results of the comparison are the distances between the primary and the secondary gear tooth surfaces, measured in the normal direction to the primary gear tooth surfaces. The results of comparison are illustrated on the primary tooth surface. GEO-Comp analyses allow independent comparison at left and right sides, or combined comparisons where results on both sides will be simultaneously shown.

IGD Tutorials

Project-Based Learning IGD - Tutorial #1

This tutorial is directed to evaluate the increment in contact and bending stresses in a spur gear drive, comprising a pinion of 21 teeth and a gear of 34 teeth and module of 3 mm, with no surface modifications and subjected to an error of alignment of 0.05 deg. in the crossing angle by using IGD - Integrated Gear Design.

Project-Based Learning IGD - Tutorial #2

This tutorial is directed to the determination of the optimal tip relief in a helical gear drive comprising a pinion of 24 teeth and a gear of 37 teeth. The gears have a module of 4 mm, a helix angle of 15.0 deg, a pressure angle of 20.0 deg, and a face width of 35.0 mm. The torque applied to the pinion is 800.0 N·m. The gears will be mounted at the reference center distance of 126.304 mm. IGD v3.5 is used for gear geometry generation and tooth contact analysis. Stress analysis is performed with ABAQUS and results postprocessed within IGD.