Multidisciplinary Senior Design Project

Standing Aid for Kitchen Tasks

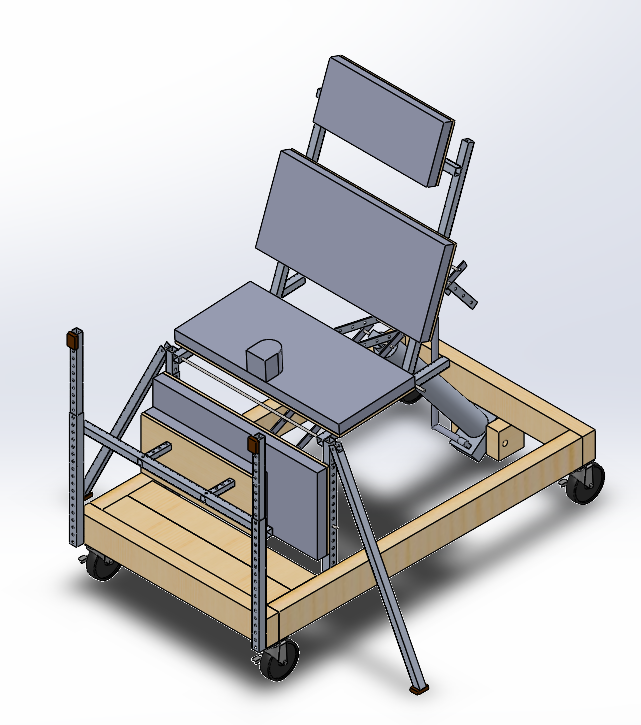

The standing aid created is an assistive device for people with disabilities like Cerebral Palsy. People with disabilities may find it difficult to stand for prolonged periods of time. This means that standing at a counter top in the kitchen is not an option. Using existing assistive devices to include people with all abilities can be difficult, especially in a kitchen. This device seeks to change that. The user of this device can both sit and stand in front of a countertop, helping them join the other people in the kitchen. The goal of this project was to deliver a functional prototype standing aid that can assist two children with Cerebral Palsy. These children should be able to sit or stand in front of their kitchen counter and should support them in either position. The device should be safe and comfortable for the children, as well as easy to use by care providers. The device should be adjustable so that as the child grows, they can continue to use the device. Ultimately, the standing device should aid the user, and increase their accessibility to the kitchen environment. The device seen here is the culmination of two semester of work for our team. We consulted two families regularly throughout this time. They helped us get an insight into the experiences of helping those with disabilities. In our first semester we uncovered what the problems were and brainstormed solutions to those problems. We used many engineering techniques to decide on the overall design of the system. When this idea was confirmed, the system was designed to a high level of detail. We had to actually change material choices around this time to conform to the requirements of the device. In the second semester we built the prototype of the stander that we had designed. There were many steps and many times where redesigns were necessary. The aluminum that was sourced, for the main components, had a wall thickness that was thicker than we expected. This meant that some of the adjustable sections of the device had to be changed. While the building process took place, different parts of the device were tested to ensure that we were on track to meet the requirements we set for the design. In the end the device was created and tested successfully.

Standing Device Design

Team Members

Connor Seavey,Jacob Schnaufer,Alex Maruna,Neil Bhasme