Robotics and Manufacturing Engineering Technology Bachelor of Science Degree

Robotics and Manufacturing Engineering Technology

Bachelor of Science Degree

- RIT /

- College of Engineering Technology /

- Academics /

- Robotics and Manufacturing Engineering Technology BS

RIT’s robotics and manufacturing engineering technology major prepares you to become an engineer well-versed in advanced manufacturing technologies and automation.

Overview for Robotics and Manufacturing Engineering Technology BS

Why Study RIT's Robotics and Manufacturing Engineering Technology Major

A New Economy Major: Robotics and manufacturing engineering technology is an RIT New Economy Major. This collection of degree programs is forward-thinking and future-forming,and prepares you to excel in the multidisciplinary nature of our modern, dynamic economy.

Gain Real-World Experience: Four required blocks of co-op mean nearly a year of hands-on, full-time paid work experience in industry.

Jobs at Industry Leading Companies: Employers hiring our students for co-ops and full-time positions include AmazonRobotics, Apple, Tesla, Lockheed Martin, Amphenol Aerospace, GE, General Motors, ITT Corp, L3Harris and more.

A Choice of Focus Areas: Tailor your degree with a focus area in one of eight technical concentrations: design and assembly modeling, design for manufacture and assembly, data acquisition and instrumentation, electronics packaging, quality control, Lean Six Sigma, manufacturing management, or plastics processing.

Accelerated Bachelor’s/Master’s Available: Earn both your bachelor’s and your master’s in less time and with a cost savings, giving you a competitive advantage in your field.

STEM-OPT Visa Eligible: The STEM Optional Practical Training (OPT) program allows full-time, on-campus international students on an F-1 student visa to stay and work in the U.S. for up to three years after graduation.

Innovations in industrial automation and manufacturing robotics are creating an increased demand for highly skilled robotics and manufacturing engineers. RIT’s robotics and manufacturing engineering technology major prepares you to become an engineer well-versed in advanced manufacturing technologies. Right now, the demand for robotics engineers, manufacturing engineers, and those skilled in designing and integrating automation into manufacturing processes is outweighing the number of students graduating with degrees in robotics engineering, resulting in outstanding employment opportunities for our graduates.

Robotic Manufacturing

The future of robotic manufacturing has arrived. Today’s manufacturing industry has evolved and its focus is now on advanced manufacturing technologies, which emphasizes:

- Automation and advanced robotics to increase productivity and execute the precise maneuvers required to assemble small electronic parts.

- Big data and cloud computing to help manufacturers track and analyze trends and statistics, monitor productivity, and engage in data-supported decision-making.

- 3D printing to decrease waste and improve output, and to reduce time needed for replacement parts.

- Artificial intelligence and the Internet of Things, which connects machines and devices and revolutionizes the way machines communicate and function.

- Augmented reality to create visual designs and simulations.

To meet the needs of the evolving manufacturing industry, RIT’s degree in robotics and manufacturing engineering technology focuses on preparing you to lead in this dynamic, ever-changing industry.

Robotics Engineering Courses

Students in the robotics and manufacturing engineering technology degree acquire skills in a wide variety of disciplines, including course work in automation and robotics, electronics manufacturing, mechatronics, advanced manufacturing technologies and processes, and integrated design. The degree’s comprehensive curriculum also includes traditional and non-traditional manufacturing processes, materials technology, computer-aided design, computer-aided manufacturing, controls for manufacturing automation, microprocessors, electrical and electronics principles, surface mount electronics manufacturing, quality control, lean manufacturing, engineering economics, and production and operations management. The uniqueness of this program is its combination of robotics and manufacturing courses and its emphasis on project-based, hands-on education.

Adding a minor in a complementary area of study deepens your expertise in the core areas of robotics manufacturing and broadens your skill set for a career in this dynamic field. These minors enhance the robotics and manufacturing engineering technology degree:

- Applied statistics

- Business analytics

- Computer science

- Cybersecurity

- Engineering management

- Manufacturing systems

- Plastics engineering and technology

- Surface mount electronics manufacturing

- Sustainable product development

High-Performance Teams and Professional Organizations

Many mechanical engineering students participate in high-octane performance teams, including the RIT Formula SAE Racing Team, the SAE Aerodesign Club, the RIT Baja SAE Team, RIT SAE Clean Snowmobile Team, and the Human-Powered Vehicle Competition team. They also are encouraged to participate in the student chapters of professional societies such as the American Society of Mechanical Engineers, the Society of Women Engineers, the National Society of Black Engineers, the Society of Hispanic Professional Engineers, the American Institute of Aeronautics and Astronautics, and the Society of Automotive Engineers.

Engineering vs. Engineering Technology

Two dynamic areas of study, both with outstanding outcomes rates. Which do you choose?

What’s the difference between engineering and engineering technology? It’s a question we’re asked all the time. While there are subtle differences in the course work between the two, choosing a major in engineering vs. engineering technology is more about identifying what you like to do and how you like to do it.

Combined Accelerated Bachelor's/Master's Degrees

Today’s careers require advanced degrees grounded in real-world experience. RIT’s Combined Accelerated Bachelor’s/Master’s Degrees enable you to earn both a bachelor’s and a master’s degree in as little as five years of study, all while gaining the valuable hands-on experience that comes from co-ops, internships, research, study abroad, and more.

- Robotics and Manufacturing Engineering Technology BS/Manufacturing and Mechanical Systems Integration MS

- +1 MBA: Students who enroll in a qualifying undergraduate degree have the opportunity to add an MBA to their bachelor’s degree after their first year of study, depending on their program. Learn how the +1 MBA can accelerate your learning and position you for success.

-

Next Steps to Enroll

Accept your offer of admission and take the next steps toward becoming an RIT Tiger.

Careers and Cooperative Education

Typical Job Titles

| Industrial Engineer | Manufacturing Engineering Associate | Process Engineer |

| Rotational Program in Manufacturing Leadership | STS Process Engineer |

Industries

-

Aerospace

-

Automotive

-

Defense

-

Manufacturing

Cooperative Education

What’s different about an RIT education? It’s the career experience you gain by completing cooperative education and internships with top companies in every single industry. You’ll earn more than a degree. You’ll gain real-world career experience that sets you apart. It’s exposure–early and often–to a variety of professional work environments, career paths, and industries.

Co-ops and internships take your knowledge and turn it into know-how. Your engineering co-ops will provide hands-on experience that enables you to apply your engineering knowledge in professional settings while you make valuable connections between classwork and real-world applications.

Students in the robotics and manufacturing engineering technology program are required to complete four co-op blocks. This typically includes one spring, one fall, and two summer blocks. You'll alternate periods of full-time study with full-time paid work experience in your career field. In some circumstances, other forms of experiential education (e.g., study abroad, research, military service) may be used to fulfill part of the co-op requirement. Each student is assigned a co-op advisor to assist in identifying and applying to co-op opportunities.

Featured Work and Profiles

-

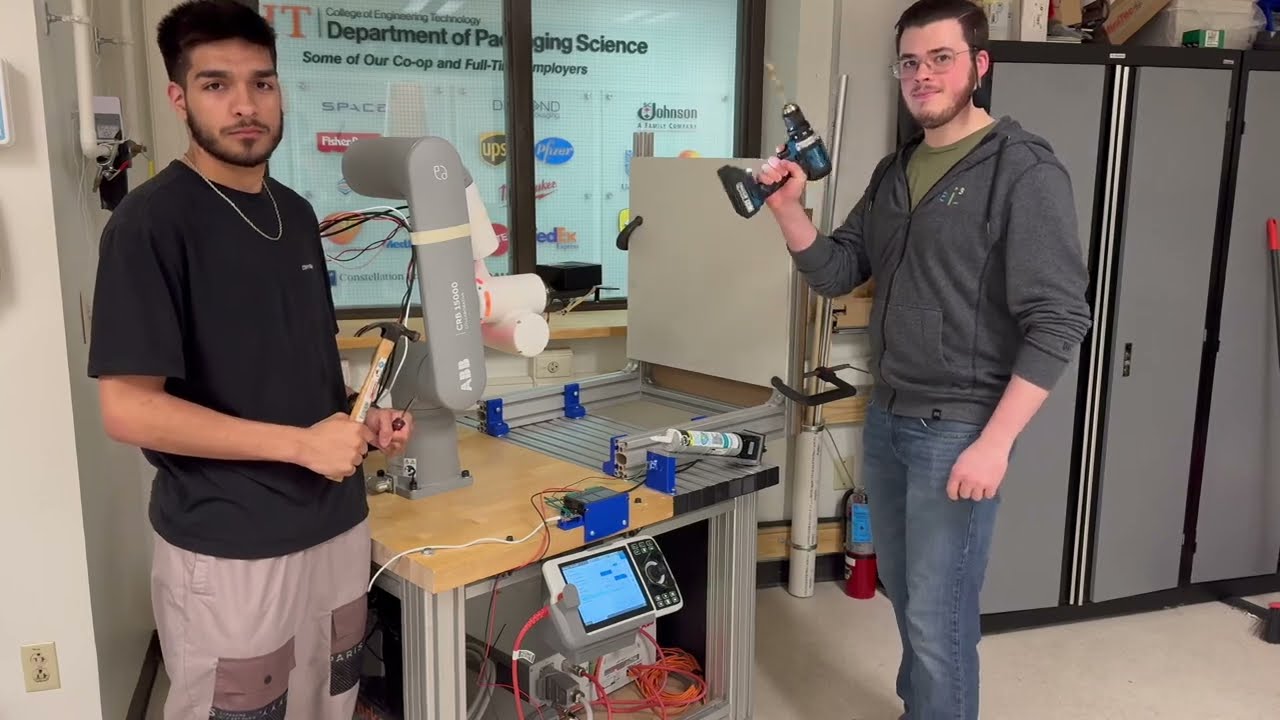

Students Use Robots for Flawless Surface Repairs

Two RIT engineering students employ a robot equipped with a vision system to detect and repair drywall defects, streamlining construction repairs with precision.

Read More about Students Use Robots for Flawless Surface Repairs -

RIT Researchers Push Boundaries of Human-Robotic Interactions

Yangming Lee, Robert Garrick Several RIT faculty researchers are pushing the boundaries of human-robotic interactions.

Read More about RIT Researchers Push Boundaries of Human-Robotic Interactions -

Jet-Fueled Co-op Boosts Student's Manufacturing Career

Alison Fink Allison Fink’s co-op at Honda Aircraft deepened her passion for hands-on manufacturing, with impactful projects and exhilarating jet deliveries setting her on a dynamic career path.

Read More about Jet-Fueled Co-op Boosts Student's Manufacturing Career -

RIT Students Analyze Steel Microstructures in Metallography Course

First-year manufacturing and mechanical engineering technology students grind, polish, and etch steel samples to study grain structures and inclusions, gaining hands-on experience in metallographic...

Read More about RIT Students Analyze Steel Microstructures in Metallography Course

Curriculum for 2024-2025 for Robotics and Manufacturing Engineering Technology BS

Current Students: See Curriculum Requirements

Robotics and Manufacturing Engineering Technology, BS degree, typical course sequence

| Course | Sem. Cr. Hrs. | |

|---|---|---|

| First Year | ||

| MATH-171 | General Education – Mathematical Perspective A: Calculus A |

3 |

This is the first course in a three-course sequence (COS-MATH-171, -172, -173). This course includes a study of precalculus, polynomial, rational, exponential, logarithmic and trigonometric functions, continuity, and differentiability. Limits of functions are used to study continuity and differentiability. The study of the derivative includes the definition, basic rules, and implicit differentiation. Applications of the derivative include optimization and related-rates problems. (Prerequisites: Completion of the math placement exam or C- or better in MATH-111 or C- or better in ((NMTH-260 or NMTH-272 or NMTH-275) and NMTH-220) or equivalent course.) Lecture 5 (Fall, Spring). | ||

| MATH-172 | General Education – Mathematical Perspective B: Calculus B |

3 |

This is the second course in three-course sequence (COS-MATH-171, -172, -173). The course includes Riemann sums, the Fundamental Theorem of Calculus, techniques of integration, and applications of the definite integral. The techniques of integration include substitution and integration by parts. The applications of the definite integral include areas between curves, and the calculation of volume. (Prerequisites: C- or better in MATH-171 or 1016-171T or 1016-281 or 1016-231 or equivalent course.) Lecture 5 (Fall, Spring). | ||

| MCET-101 | Fundamentals of Engineering |

3 |

Students will apply engineering problem solving methods used in industry to complete projects involving engineering topics such as mechanics, circuits, robotics, and thermodynamics. Software tools are used to model their designs, perform design calculations, collect and analyze data. Finally, students will present their work professionally using both written and oral communication software. The goal of the class is to have students become familiar with the many aspects of mechanical engineering through hands on, experiential learning and prepares them to work professionally and effectively in a team setting both in college and in industry. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EEET-BS or CPET-BS or ENGTEH-UND students.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| MCET-110 | Foundations of Metals |

2 |

This class explores the commonly used engineering metals. Differentiation of materials, with a focus on metals, is made based on an understanding and control of fundamental material properties. This knowledge of properties and materials then informs analysis of which metals are selected for various applications. Corrosion and its mitigation are explored. Materials selection software and internet resources are used. (Prerequisites: This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS or ENGTEH-UND students.

Corequisites: MCET-111 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| MCET-111 | Characterization of Metals Lab |

1 |

This lab class accompanies MCET-110 Foundations of Materials. An emphasis is placed on determining material, primarily metals, properties though experimentation and references, and analyzing why a particular material was selected for an application based on the materials properties. Differentiation of materials families is made based on properties. A variety of discovery activities are used to explore the world of metals, including labs of various types, materials selection software, and internet resources. (Co-requisites: MCET-110 or equivalent course.) Lab 1 (Fall, Spring). | ||

| MCET-150 | Engineering Communication and Tolerancing |

3 |

A course that integrates basic engineering techniques. Topics will emphasize the design and communication of components through the use of hand sketching, solid modeling, dimensioning, tolerancing, and current GD&T standards. Students will be expected to design, build, inspect, and integrate GD&T into designs. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS or ENGTEH-UND students.) Lecture 3, Recitation 1 (Spring). | ||

| PHYS-111 | General Education – Natural Science Inquiry Perspective: College Physics I |

4 |

This is an introductory course in algebra-based physics focusing on mechanics and waves. Topics include kinematics, planar motion, Newton’s laws, gravitation; rotational kinematics and dynamics; work and energy; momentum and impulse; conservation laws; simple harmonic motion; waves; data presentation/analysis and error propagation. The course is taught using both traditional lectures and a workshop format that integrates material traditionally found in separate lecture, recitation, and laboratory settings. Attendance at the scheduled evening sessions of this class is required for exams. There will be 2 or 3 of these evening exams during the semester. Competency in algebra, geometry and trigonometry is required. Lab 4, Lecture 2 (Fall, Spring, Summer). | ||

| UWRT-150 | General Education – FYW: Writing Seminar (WI) |

3 |

Writing Seminar is a three-credit course limited to 19 students per section. The course is designed to develop first-year students’ proficiency in analytical and rhetorical reading and writing, and critical thinking. Students will read, understand, and interpret a variety of non-fiction texts representing different cultural perspectives and/or academic disciplines. These texts are designed to challenge students intellectually and to stimulate their writing for a variety of contexts and purposes. Through inquiry-based assignment sequences, students will develop academic research and literacy practices that will be further strengthened throughout their academic careers. Particular attention will be given to the writing process, including an emphasis on teacher-student conferencing, critical self-assessment, class discussion, peer review, formal and informal writing, research, and revision. Small class size promotes frequent student-instructor and student-student interaction. The course also emphasizes the principles of intellectual property and academic integrity for both current academic and future professional writing. Lecture 3 (Fall, Spring, Summer). | ||

| RMET-105 | Machine Tools Lab |

1 |

Proficiency with traditional machine shop tools will be demonstrated with an emphasis on safety. Students will demonstrate their abilities to interpret drawings and select the appropriate equipment needed to produce each part. Parts built will be inspected by the student to verify the meeting of part requirements. Students will repair/replace any parts that are found to be out of specifications. Inspection tools will be utilized in the product validation requirement of the course. Topics will be experimentally validated through the creation of mechanical parts that will be assembled into a final product. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS major students.) Lab 2 (Fall, Spring). | ||

| RMET-120 | Manufacturing Processes |

3 |

This course will focus on the understanding and application of manufacturing processes. Students will be challenged to discover and learn how typical piece parts and assemblies are manufactured. Topics include material properties and the following process families: casting, material removal, deformation, consolidation, powder metallurgy, and plastics fabrication. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or MANUFSY-MN or ENGTEH-UND students.) Lecture 3 (Fall, Spring). | ||

| YOPS-10 | RIT 365: RIT Connections |

0 |

RIT 365 students participate in experiential learning opportunities designed to launch them into their career at RIT, support them in making multiple and varied connections across the university, and immerse them in processes of competency development. Students will plan for and reflect on their first-year experiences, receive feedback, and develop a personal plan for future action in order to develop foundational self-awareness and recognize broad-based professional competencies. (This class is restricted to incoming 1st year or global campus students.) Lecture 1 (Fall, Spring). | ||

General Education - Global Perspective |

3 | |

General Education - Artistic Perspective |

3 | |

| Second Year | ||

| CPET-121 | Computational Problem Solving I |

3 |

This is the first course in a two-course sequence in computational problem solving of engineering and scientific problems. The problems solved will stress the application of sequence, selection, repetitive, invocation operations, and arrays. The development of proper testing procedures to ensure computational accuracy will be stressed. Students, upon successful completion of this course, will be able to analyze introductory engineering and scientific problems, design, code, test, and document procedural software solutions. Lec/Lab 4 (Fall, Spring). | ||

| EEET-115 | Circuits I |

3 |

This course develops student skills to analyze and design DC and AC circuits. DC topics include resistance; Ohm’s Law; current and voltage division; simplification of series, parallel, and series-parallel circuits; Kirchhoff’s Voltage and Kirchhoff’s Current Laws, and nodal analysis. Additional circuit analysis concepts covered include Thevenin theorem, superposition theorem, and R-C and R-L transient analysis. AC circuit analysis topics include sinusoidal waveforms as forcing functions; basic resistive, capacitive, and inductive elements; phasors; average power and series AC circuit analysis. Reactance and impedance are introduced and used to solve AC series circuits. (Co-requisite: EEET-116 and MATH-111 or MATH-171 or MATH-181 or MATH-181A or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| EEET-116 | Circuits I Laboratory |

1 |

This laboratory develops skills and practice in the construction, measurement, and analysis of DC and introductory AC circuits. Standard laboratory equipment is introduced and utilized to measure resistance, voltage, and current in basic and relatively complex circuit configurations. Measurements are employed to demonstrate Ohm's Law, Kirchoff’s Voltage Law, Kirchoff’s Current Law, current division, and voltage division. Circuit simulation software is used to support calculations and establish a baseline for comparison. Students collaborate within teams during the laboratory experience. (Co-requisite: EEET-115 or equivalent course.) Lab 2 (Fall, Spring). | ||

| ENGT-95 | Career Seminar |

0 |

This course is an introduction to the cooperative educational program at RIT, the programs in the department, and RIT resources. Topics include engineering technology vs. engineering, review of resources available at RIT, the cooperative education placement process, and the ethical expectations of employers for co-op students and RIT during a job search. Seminar 1 (Fall, Spring). | ||

| MATH-211 | Elements of Multivariable Calculus and Differential Equations |

3 |

This course includes an introduction to differential equations, Laplace transforms, numerical methods in differential equations, and the calculus of functions of two variables. The emphasis is on the application of these topics to problems in engineering technology. (Prerequisites: C- or better MATH-172 or MATH-182 or MATH 182A or 1016-232 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| MECA-290 | Mechanics for Mechatronics |

3 |

Students will learn the applications of mechanics through the examination of mechatronic elements and systems. It is broken into two parts: Fundamentals of Mechanics of Materials (a.k.a. Strength of Materials) You will learn to calculate stresses and deflections in members loaded under axial, transverse, and torsional loads. Fundamentals of Dynamics You will learn to use kinematics (study of motion without regard to forces) and kinetics (study of forces required to cause motion, e.g., Newton’s Laws of Motion) to calculate the motion of particles and rigid bodies in motion. You will also gain experience with computational tools, laboratory equipment, experimental methods, teamwork, project management and communications as you complete project assignments. (Prerequisites: C- or better in MCET-220 or MECE-103 or CVET-210 or equivalent course.

Co-requisite: MCET-110 or NETS-110 or MECE-305 or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| MCET-220 | Principles of Statics |

3 |

This course provides an introduction to the analysis and design of structures and machines. Students learn to calculate unknown forces using the concept of equilibrium and free body diagrams and to calculate simple stresses and deflections for axially loaded members. Topics include forces, moments, free body diagrams, equilibrium, friction, stress, strain, and deflection. Examples are drawn from mechanical, manufacturing, and civil engineering technology. Lecture 3, Recitation 1 (Fall, Spring). | ||

| PHYS-112 | College Physics II |

4 |

This course is an introduction to algebra-based physics focusing on thermodynamics, electricity and magnetism, and elementary topics in modern physics. Topics include heat and temperature, laws of thermodynamics, electric and magnetic forces and fields, DC and AC electrical circuits, electromagnetic induction, the concept of the photon, and the Bohr model of the atom. The course is taught using both traditional lectures and a workshop format that integrates material traditionally found in separate lecture, recitation, and laboratory settings. Attendance at the scheduled evening sessions of this class is required for exams. There will be 2 or 3 of these evening exams during the semester. (Prerequisites: PHYS-111 or PHYS-211 or equivalent course.) Lab 4, Lecture 2 (Fall, Spring). | ||

| RMET-340 | Automation Control Systems |

2 |

This course will provide a thorough understanding of the manufacturing automation principles, practices and system integration. Students will design a fully automated control system from selection of components, specifying the Programmable Logic Controller (PLC), and developing the ladder logic required to operate the system. Students will have the tools to effectively be able to fully design an automated control system as in done in varying industries. (Co-requisite: RMET-341 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| RMET-341 | Automation Control Systems Lab |

1 |

This course will provide a thorough hands-on experience in using Programmable Logic Controllers (PLCs) for manufacturing automation and system integration. Industry best practices for programming PLCs and the essentials of Human Machine Interface (HMI) for data entry, manipulation, and recording system status will be included. (Co-requisites: RMET-340 or equivalent course.) Lab 2 (Fall, Spring). | ||

| RMET-585 | Robots & Automation |

|

This course focuses on the technology and application of robots and automation in the modern manufacturing environment. It will provide a thorough understanding of robotic hardware and software. The hardware aspects include robot configurations, drive mechanisms, power systems (hydraulic, pneumatic, and servo actuators), end-effectors and end-of-arm-tooling, sensors, control systems, machine vision, programming, safety, and integration. The software aspect deals with the various methods of textual and lead through programming commonly found on commercial robotic systems, as well as simulation systems offered by robot manufacturers. Digital Interfacing of robots with other automation components such as programmable logic controllers, computer-controlled machines, conveyors, is introduced. Robotic cell design and the socio-economic impact of robotics are also discussed. This course also has a strong experiential component that emphasizes hands-on training. This course may be cross-listed with RMET-685. Students may not take and receive credit for this course if they have already taken RMET-685. College-level programming experience in at least one computer language strongly recommended. (Prerequisites: MCET-220 or CVET-210 or MECE-103 or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

General Education – Ethical Perspective |

3 | |

General Education - Social Perspective |

3 | |

| Third Year | ||

| CHMG-131 | General Education- Scientific Principles Perspective: General Chemistry for Engineers |

3 |

This rigorous course is primarily for, but not limited to, engineering students. Topics include an introduction to some basic concepts in chemistry, stoichiometry, First Law of Thermodynamics, thermochemistry, electronic theory of composition and structure, and chemical bonding. The lecture is supported by workshop-style problem sessions. Offered in traditional and online format. Lecture 3 (Fall, Spring). | ||

| CPET-133 | Introduction to Digital and Microcontroller Systems |

3 |

This course introduces students to the underlying building blocks of digital system and microcontroller design. Digital systems topics that are covered include: number systems, truth tables, Boolean algebra, combinational and sequential logic, and finite state machines. A microcontroller is used to teach register programming, reading and writing digital I/O, bitwise operations and bit-masking and microprocessor architecture. Laboratory exercises are designed to illustrate concepts, reinforce analysis and design skills, and develop instrumentation techniques associated with the lecture topics. Lab 2, Lecture 2 (Fall). | ||

| RMET-545 | Electronics Manufacturing |

3 |

This course provides a thorough understanding of the technology, components, equipment, materials and manufacturing process for through hole technology and surface mount technology electronics manufacturing. Students will develop a strong foundation needed for advanced work in surface mount technology (SMT). Topics in Design for Manufacturing are also considered for high volume vs. low volume manufacturing. Students may only receive credit for this course or RMET-645, not both. Lecture 3, Recitation 1 (Fall). | ||

| STAT-145 | Introduction to Statistics I |

3 |

This course introduces statistical methods of extracting meaning from data, and basic inferential statistics. Topics covered include data and data integrity, exploratory data analysis, data visualization, numeric summary measures, the normal distribution, sampling distributions, confidence intervals, and hypothesis testing. The emphasis of the course is on statistical thinking rather than computation. Statistical software is used. (Prerequisites: Any 100 level MATH course, or NMTH-260 or NMTH-272 or NMTH-275 or (NMTH-250 with a C- or better) or a Math Placement Exam score of at least 35.) Lecture 3 (Fall, Spring, Summer). | ||

| RMET-499 | RMET Co-Op (Spring, Summer) |

3 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

Choose one of the following: |

3 | |

COMM-142 Introduction to Technical Communication (WI) |

||

COMM-221 Public Relations Writing (WI) |

||

COMM-253 Communication (WI) |

||

ENGL-260 Written Argument (WI) |

||

SOIS-325 Business Communication (WI) |

||

| Fourth Year | ||

| MCET-210 | Foundations of Non-Metallic Materials |

2 |

This course will cover the process of selecting a best material for a given design application with a focus on polymeric materials. To support this process material families, strengthening mechanisms, and degradation mechanisms and prevention will be studied. The materials selection process will include economic, ecological, and ethical considerations. An emphasis is placed on the interrelationship of structure, process, and properties. This class expands upon concepts presented in MCET-110. (Prerequisites: C- or better in (CHMG-131 or CHMG-141 or CHEM-151) and (MCET-110 and MCET-111) or (NETS-110 and NETS-111) or (MECE-304 or MECE-305 and MECE-306) or equivalent courses.

Corequisite: MCET-211 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| MCET-211 | Characterization of Non-Metallic Materials Lab |

1 |

This course will consist of laboratory experiences which focus on property characterization of the properties of polymeric materials. (Co-requisites: MCET-210 or equivalent course.) Lab 2 (Fall, Spring). | ||

| MECA-335 | Applications of Fluid Power and Heat Transfer |

3 |

This course focuses on fluid power, fluid mechanics, flow mechanisms, heat transfer, and the ideal gas laws in the context of mechatronic and robotic systems. Students learn to design and construct pneumatic and hydraulic circuits and controls. Issues of fluid forces, flow characterization, efficiency, losses are applied to pumps, compressors, accumulators, and control valves. Basics of heat transfer, flow mechanisms, and ideal gas laws are applied to robotic and mechatronic systems Laboratory activities put the theory into practice. The course culminates in a comprehensive project where students design and build an electro-fluid power system to solve a practical problem. (Prerequisites: C- or better in MCET-220 or MECE-103 or CVET-210 or equivalent course.) Lab 1, Lecture 3 (Fall, Spring). | ||

| RMET-420 | Quality Engineering Principles |

3 |

This course is designed to introduce the student to techniques required to maintain and improve quality within manufacturing organizations and the service sector through the use of statistical methodologies. The course covers concepts of quality, quality managements and assurance, product quality, design of quality control chart, statistical process control, and quality improvement through design by considering concept development and implementation. Traditional and modern quality systems will be discussed including the work of such quality gurus like Taguchi, Deming, Juran, and Shewhart. (Prerequisites: STAT-145 or STAT-205 or STAT-251 or MATH-251 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| RMET-450 | Lean Production & Supply Chain Operations |

3 |

This course is designed to provide the student with knowledge and skills of contemporary theories and practices in operations and supply chain management employed by world class manufacturing organizations. Students are introduced to topics that include forecasting, aggregate planning, inventory management, capacity management, and supply chain management. Integrated with these topics are lean excellence tools VSM, 5S, Kanban, OEE and Standard Work Practices, Cycle Time Analysis. (Prerequisites: STAT-145 or STAT-205 or STAT-251 or MATH-251 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| RMET-460 | Integrated Design for Manufacture & Assembly |

3 |

Integrated design for manufacture and assembly manufacturing processes are expanded and applied to the design process. Part concepts will be considered for various manufacturing processes to determine which process will yield the lowest cost part that meets all product functional requirements. Students will learn the DFMA methodology for making decisions to analyze the costs associated with their product concepts. Designs will consider the tooling that is required in product build and will understand the interrelationships between decisions and the cost associated with manufacture and service of the product. At the conclusion of the course students will be able to effectively design parts and assemblies for manufacture, assembly, and service. Costing will be considered at every step of the design process. (Prerequisites: RMET-120 or NETS-120 or equivalent course.) Lecture 3 (Spring). | ||

| RMET-499 | RMET Co-op |

0 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

| STAT-146 | Introduction to Statistics II |

4 |

This course is an elementary introduction to the topics of regression and analysis of variance. The statistical software package Minitab will be used to reinforce these techniques. The focus of this course is on business applications. This is a general introductory statistics course and is intended for a broad range of programs. (Prerequisites: STAT-145 or equivalent course.) Lecture 6 (Fall, Spring, Summer). | ||

General Education – Immersion 1, 2 |

6 | |

General Education – Elective |

3 | |

Open Elective |

3 | |

| Fifth Year | ||

| RMET-499 | RMET Co-op (fall) |

0 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

| RMET-565 | RMET Engineering Technology Capstone Project (WI-PR) |

4 |

This is the Engineering Technology Common Capstone Project course where students address open-ended problems. Emphasis is placed on teamwork, the design process, and project management tools addressing project scope, schedule, milestones, deliverables, risk, and cost. The course also focuses on developing oral, written and interpersonal communication skills. In this course, cross-disciplinary student teams develop their proposed mechanism or machine after identifying customer needs, and possible alternative concepts. The mechanism or machine must include sufficiently complex mechanical and electrical subsystems, a control system, and a manufacturing system design. The subsystems of the design must be effectively integrated to achieve proper operation of the mechanism or machine. The final system design must be supported by sound engineering analyses and by engineering designs necessary to build a prototype. The design will be implemented through further analysis, testing, documentation, demonstration, and presentation of a fully functional prototype. This course is intended to be taken as a capstone design experience near the conclusion of the student's program of study. (Prerequisites: RMET-340 and RMET-585 and RMET-420 and RMET-460 or equivalent courses.

Co-requisites: RMET-545 or equivalent course.) Lab 3, Lecture 3 (Fall, Spring). | ||

Open Electives |

7 | |

General Education – Immersion 3 |

3 | |

| Total Semester Credit Hours | 124 |

|

Please see General Education Curriculum (GE) for more information.

(WI) Refers to a writing intensive course within the major.

Please see Wellness Education Requirement for more information. Students completing bachelor's degrees are required to complete two different Wellness courses.

Combined Accelerated Bachelor's/Master's Degrees

The curriculum below outlines the typical course sequence(s) for combined accelerated degrees available with this bachelor's degree.

Robotics and Manufacturing Engineering Technology, BS degree/Manufacturing and Mechanical Systems Integration, MS degree, typical course sequence

| Course | Sem. Cr. Hrs. | |

|---|---|---|

| First Year | ||

| MATH-171 | Calculus A (General Education – Mathematical Perspective A) |

3 |

This is the first course in a three-course sequence (COS-MATH-171, -172, -173). This course includes a study of precalculus, polynomial, rational, exponential, logarithmic and trigonometric functions, continuity, and differentiability. Limits of functions are used to study continuity and differentiability. The study of the derivative includes the definition, basic rules, and implicit differentiation. Applications of the derivative include optimization and related-rates problems. (Prerequisites: Completion of the math placement exam or C- or better in MATH-111 or C- or better in ((NMTH-260 or NMTH-272 or NMTH-275) and NMTH-220) or equivalent course.) Lecture 5 (Fall, Spring). | ||

| MATH-172 | Calculus B (General Education – Mathematical Perspective B) |

3 |

This is the second course in three-course sequence (COS-MATH-171, -172, -173). The course includes Riemann sums, the Fundamental Theorem of Calculus, techniques of integration, and applications of the definite integral. The techniques of integration include substitution and integration by parts. The applications of the definite integral include areas between curves, and the calculation of volume. (Prerequisites: C- or better in MATH-171 or 1016-171T or 1016-281 or 1016-231 or equivalent course.) Lecture 5 (Fall, Spring). | ||

| MCET-101 | Fundamentals of Engineering |

3 |

Students will apply engineering problem solving methods used in industry to complete projects involving engineering topics such as mechanics, circuits, robotics, and thermodynamics. Software tools are used to model their designs, perform design calculations, collect and analyze data. Finally, students will present their work professionally using both written and oral communication software. The goal of the class is to have students become familiar with the many aspects of mechanical engineering through hands on, experiential learning and prepares them to work professionally and effectively in a team setting both in college and in industry. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EEET-BS or CPET-BS or ENGTEH-UND students.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| MCET-110 | Foundations of Metals |

2 |

This class explores the commonly used engineering metals. Differentiation of materials, with a focus on metals, is made based on an understanding and control of fundamental material properties. This knowledge of properties and materials then informs analysis of which metals are selected for various applications. Corrosion and its mitigation are explored. Materials selection software and internet resources are used. (Prerequisites: This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS or ENGTEH-UND students.

Corequisites: MCET-111 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| MCET-111 | Characterization of Metals Lab |

1 |

This lab class accompanies MCET-110 Foundations of Materials. An emphasis is placed on determining material, primarily metals, properties though experimentation and references, and analyzing why a particular material was selected for an application based on the materials properties. Differentiation of materials families is made based on properties. A variety of discovery activities are used to explore the world of metals, including labs of various types, materials selection software, and internet resources. (Co-requisites: MCET-110 or equivalent course.) Lab 1 (Fall, Spring). | ||

| MCET-150 | Engineering Communication and Tolerancing |

3 |

A course that integrates basic engineering techniques. Topics will emphasize the design and communication of components through the use of hand sketching, solid modeling, dimensioning, tolerancing, and current GD&T standards. Students will be expected to design, build, inspect, and integrate GD&T into designs. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS or ENGTEH-UND students.) Lecture 3, Recitation 1 (Spring). | ||

| PHYS-111 | College Physics I (General Education – Natural Science Inquiry Perspective) |

4 |

This is an introductory course in algebra-based physics focusing on mechanics and waves. Topics include kinematics, planar motion, Newton’s laws, gravitation; rotational kinematics and dynamics; work and energy; momentum and impulse; conservation laws; simple harmonic motion; waves; data presentation/analysis and error propagation. The course is taught using both traditional lectures and a workshop format that integrates material traditionally found in separate lecture, recitation, and laboratory settings. Attendance at the scheduled evening sessions of this class is required for exams. There will be 2 or 3 of these evening exams during the semester. Competency in algebra, geometry and trigonometry is required. Lab 4, Lecture 2 (Fall, Spring, Summer). | ||

| RMET-105 | Machine Tools Lab |

1 |

Proficiency with traditional machine shop tools will be demonstrated with an emphasis on safety. Students will demonstrate their abilities to interpret drawings and select the appropriate equipment needed to produce each part. Parts built will be inspected by the student to verify the meeting of part requirements. Students will repair/replace any parts that are found to be out of specifications. Inspection tools will be utilized in the product validation requirement of the course. Topics will be experimentally validated through the creation of mechanical parts that will be assembled into a final product. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or EMET-BS major students.) Lab 2 (Fall, Spring). | ||

| RMET-120 | Manufacturing Processes |

3 |

This course will focus on the understanding and application of manufacturing processes. Students will be challenged to discover and learn how typical piece parts and assemblies are manufactured. Topics include material properties and the following process families: casting, material removal, deformation, consolidation, powder metallurgy, and plastics fabrication. (This class is restricted to MCET-BS or MECA-BS or RMET-BS or MANUFSY-MN or ENGTEH-UND students.) Lecture 3 (Fall, Spring). | ||

| UWRT-150 | FYW: Writing Seminar (WI) (General Education – First Year Writing) |

3 |

Writing Seminar is a three-credit course limited to 19 students per section. The course is designed to develop first-year students’ proficiency in analytical and rhetorical reading and writing, and critical thinking. Students will read, understand, and interpret a variety of non-fiction texts representing different cultural perspectives and/or academic disciplines. These texts are designed to challenge students intellectually and to stimulate their writing for a variety of contexts and purposes. Through inquiry-based assignment sequences, students will develop academic research and literacy practices that will be further strengthened throughout their academic careers. Particular attention will be given to the writing process, including an emphasis on teacher-student conferencing, critical self-assessment, class discussion, peer review, formal and informal writing, research, and revision. Small class size promotes frequent student-instructor and student-student interaction. The course also emphasizes the principles of intellectual property and academic integrity for both current academic and future professional writing. Lecture 3 (Fall, Spring, Summer). | ||

| YOPS-10 | RIT 365: RIT Connections |

0 |

RIT 365 students participate in experiential learning opportunities designed to launch them into their career at RIT, support them in making multiple and varied connections across the university, and immerse them in processes of competency development. Students will plan for and reflect on their first-year experiences, receive feedback, and develop a personal plan for future action in order to develop foundational self-awareness and recognize broad-based professional competencies. (This class is restricted to incoming 1st year or global campus students.) Lecture 1 (Fall, Spring). | ||

General Education - Global Perspective |

3 | |

General Education - Artistic Perspective |

3 | |

| Second Year | ||

| CPET-121 | Computational Problem Solving I (General Education – Elective) |

3 |

This is the first course in a two-course sequence in computational problem solving of engineering and scientific problems. The problems solved will stress the application of sequence, selection, repetitive, invocation operations, and arrays. The development of proper testing procedures to ensure computational accuracy will be stressed. Students, upon successful completion of this course, will be able to analyze introductory engineering and scientific problems, design, code, test, and document procedural software solutions. Lec/Lab 4 (Fall, Spring). | ||

| EEET-115 | Circuits I |

3 |

This course develops student skills to analyze and design DC and AC circuits. DC topics include resistance; Ohm’s Law; current and voltage division; simplification of series, parallel, and series-parallel circuits; Kirchhoff’s Voltage and Kirchhoff’s Current Laws, and nodal analysis. Additional circuit analysis concepts covered include Thevenin theorem, superposition theorem, and R-C and R-L transient analysis. AC circuit analysis topics include sinusoidal waveforms as forcing functions; basic resistive, capacitive, and inductive elements; phasors; average power and series AC circuit analysis. Reactance and impedance are introduced and used to solve AC series circuits. (Co-requisite: EEET-116 and MATH-111 or MATH-171 or MATH-181 or MATH-181A or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| EEET-116 | Circuits I Lab |

1 |

This laboratory develops skills and practice in the construction, measurement, and analysis of DC and introductory AC circuits. Standard laboratory equipment is introduced and utilized to measure resistance, voltage, and current in basic and relatively complex circuit configurations. Measurements are employed to demonstrate Ohm's Law, Kirchoff’s Voltage Law, Kirchoff’s Current Law, current division, and voltage division. Circuit simulation software is used to support calculations and establish a baseline for comparison. Students collaborate within teams during the laboratory experience. (Co-requisite: EEET-115 or equivalent course.) Lab 2 (Fall, Spring). | ||

| ENGT-95 | Career Seminar |

0 |

This course is an introduction to the cooperative educational program at RIT, the programs in the department, and RIT resources. Topics include engineering technology vs. engineering, review of resources available at RIT, the cooperative education placement process, and the ethical expectations of employers for co-op students and RIT during a job search. Seminar 1 (Fall, Spring). | ||

| MATH-211 | Elements of Multivariable Calculus and Differential Equations (General Education – Elective) |

3 |

This course includes an introduction to differential equations, Laplace transforms, numerical methods in differential equations, and the calculus of functions of two variables. The emphasis is on the application of these topics to problems in engineering technology. (Prerequisites: C- or better MATH-172 or MATH-182 or MATH 182A or 1016-232 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| MCET-220 | Principles of Statics |

3 |

This course provides an introduction to the analysis and design of structures and machines. Students learn to calculate unknown forces using the concept of equilibrium and free body diagrams and to calculate simple stresses and deflections for axially loaded members. Topics include forces, moments, free body diagrams, equilibrium, friction, stress, strain, and deflection. Examples are drawn from mechanical, manufacturing, and civil engineering technology. Lecture 3, Recitation 1 (Fall, Spring). | ||

| MECA-290 | Mechanics for Mechatronics |

3 |

Students will learn the applications of mechanics through the examination of mechatronic elements and systems. It is broken into two parts: Fundamentals of Mechanics of Materials (a.k.a. Strength of Materials) You will learn to calculate stresses and deflections in members loaded under axial, transverse, and torsional loads. Fundamentals of Dynamics You will learn to use kinematics (study of motion without regard to forces) and kinetics (study of forces required to cause motion, e.g., Newton’s Laws of Motion) to calculate the motion of particles and rigid bodies in motion. You will also gain experience with computational tools, laboratory equipment, experimental methods, teamwork, project management and communications as you complete project assignments. (Prerequisites: C- or better in MCET-220 or MECE-103 or CVET-210 or equivalent course.

Co-requisite: MCET-110 or NETS-110 or MECE-305 or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| RMET-499 | MFET Co-op (summer) |

0 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

| RMET-340 | Automation Control Systems |

2 |

This course will provide a thorough understanding of the manufacturing automation principles, practices and system integration. Students will design a fully automated control system from selection of components, specifying the Programmable Logic Controller (PLC), and developing the ladder logic required to operate the system. Students will have the tools to effectively be able to fully design an automated control system as in done in varying industries. (Co-requisite: RMET-341 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| RMET-341 | Automation Control Systems Lab |

1 |

This course will provide a thorough hands-on experience in using Programmable Logic Controllers (PLCs) for manufacturing automation and system integration. Industry best practices for programming PLCs and the essentials of Human Machine Interface (HMI) for data entry, manipulation, and recording system status will be included. (Co-requisites: RMET-340 or equivalent course.) Lab 2 (Fall, Spring). | ||

| RMET-585 | Robots & Automation |

3 |

This course focuses on the technology and application of robots and automation in the modern manufacturing environment. It will provide a thorough understanding of robotic hardware and software. The hardware aspects include robot configurations, drive mechanisms, power systems (hydraulic, pneumatic, and servo actuators), end-effectors and end-of-arm-tooling, sensors, control systems, machine vision, programming, safety, and integration. The software aspect deals with the various methods of textual and lead through programming commonly found on commercial robotic systems, as well as simulation systems offered by robot manufacturers. Digital Interfacing of robots with other automation components such as programmable logic controllers, computer-controlled machines, conveyors, is introduced. Robotic cell design and the socio-economic impact of robotics are also discussed. This course also has a strong experiential component that emphasizes hands-on training. This course may be cross-listed with RMET-685. Students may not take and receive credit for this course if they have already taken RMET-685. College-level programming experience in at least one computer language strongly recommended. (Prerequisites: MCET-220 or CVET-210 or MECE-103 or equivalent course.) Lecture 3, Recitation 1 (Fall, Spring). | ||

| PHYS-112 | General Education – Elective: College Physics II |

4 |

This course is an introduction to algebra-based physics focusing on thermodynamics, electricity and magnetism, and elementary topics in modern physics. Topics include heat and temperature, laws of thermodynamics, electric and magnetic forces and fields, DC and AC electrical circuits, electromagnetic induction, the concept of the photon, and the Bohr model of the atom. The course is taught using both traditional lectures and a workshop format that integrates material traditionally found in separate lecture, recitation, and laboratory settings. Attendance at the scheduled evening sessions of this class is required for exams. There will be 2 or 3 of these evening exams during the semester. (Prerequisites: PHYS-111 or PHYS-211 or equivalent course.) Lab 4, Lecture 2 (Fall, Spring). | ||

General Education – Ethical Perspective |

3 | |

General Education – Social Perspective |

3 | |

| Third Year | ||

| CHMG-131 | General Chemistry for Engineers (General Education - Scientific Principles Perspective) |

3 |

This rigorous course is primarily for, but not limited to, engineering students. Topics include an introduction to some basic concepts in chemistry, stoichiometry, First Law of Thermodynamics, thermochemistry, electronic theory of composition and structure, and chemical bonding. The lecture is supported by workshop-style problem sessions. Offered in traditional and online format. Lecture 3 (Fall, Spring). | ||

| CPET-133 | Introduction to Digital and Microcontroller Systems |

3 |

This course introduces students to the underlying building blocks of digital system and microcontroller design. Digital systems topics that are covered include: number systems, truth tables, Boolean algebra, combinational and sequential logic, and finite state machines. A microcontroller is used to teach register programming, reading and writing digital I/O, bitwise operations and bit-masking and microprocessor architecture. Laboratory exercises are designed to illustrate concepts, reinforce analysis and design skills, and develop instrumentation techniques associated with the lecture topics. Lab 2, Lecture 2 (Fall). | ||

| RMET-450 | Lean Production & Supply Chain Operations |

3 |

This course is designed to provide the student with knowledge and skills of contemporary theories and practices in operations and supply chain management employed by world class manufacturing organizations. Students are introduced to topics that include forecasting, aggregate planning, inventory management, capacity management, and supply chain management. Integrated with these topics are lean excellence tools VSM, 5S, Kanban, OEE and Standard Work Practices, Cycle Time Analysis. (Prerequisites: STAT-145 or STAT-205 or STAT-251 or MATH-251 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| RMET-460 | Integrated Design for Manufacture & Assembly |

3 |

Integrated design for manufacture and assembly manufacturing processes are expanded and applied to the design process. Part concepts will be considered for various manufacturing processes to determine which process will yield the lowest cost part that meets all product functional requirements. Students will learn the DFMA methodology for making decisions to analyze the costs associated with their product concepts. Designs will consider the tooling that is required in product build and will understand the interrelationships between decisions and the cost associated with manufacture and service of the product. At the conclusion of the course students will be able to effectively design parts and assemblies for manufacture, assembly, and service. Costing will be considered at every step of the design process. (Prerequisites: RMET-120 or NETS-120 or equivalent course.) Lecture 3 (Spring). | ||

| RMET-499 | RMET- Co-op |

0 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

| RMET-545 | Electronics Manufacturing |

3 |

This course provides a thorough understanding of the technology, components, equipment, materials and manufacturing process for through hole technology and surface mount technology electronics manufacturing. Students will develop a strong foundation needed for advanced work in surface mount technology (SMT). Topics in Design for Manufacturing are also considered for high volume vs. low volume manufacturing. Students may only receive credit for this course or RMET-645, not both. Lecture 3, Recitation 1 (Fall). | ||

| RMET-600 | MMSI Graduate Seminar |

0 |

This course provides students that are new to the MMSI program an opportunity to develop an understanding of the department’s research activities. The students will become more knowledgeable about the Manufacturing & Mechanical Systems Integration program, career options, the capstone and thesis project process (finding an advisor, required documentation and policies regarding completing a project on co-op) and department policies and procedures related to successful completion of the MMSI program. (This course is restricted to students in MMSI-MS, MCET/MMSI-BSMS, EMET/MMSI-BSMS, MECA/MMSI-BSMS, RMET/MMSI-BSMS programs.) Seminar 2 (Fall). | ||

| RMET-650 | Manufacturing and Mechanical Systems Fundamentals |

3 |

This course is intended to help students learn to think like systems engineers. This course will provide a thorough understanding of the systems fundamentals, its design, modeling, and integration. Topics include a thorough coverage of systems architecture, conceptualization, modeling, development and management. Students in this course will be taught industry practices for systems engineering and management from concept stage to post implementation stage. System engineering and modeling tools will also be introduced to assist with the conceptualization, development, and implementation of systems. (This course is restricted to students in MMSI-MS, MCET/MMSI-BSMS, EMET/MMSI-BSMS, MECA/MMSI-BSMS, RMET/MMSI-BSMS programs.) Lecture 3 (Fall). | ||

| Choose one of the following: | 3 |

|

| RMET-730 | Six Sigma for Design and Manufacturing |

|

This course presents the philosophy and tools that will enable participants to develop quality strategies and drive process improvements that are linked to and integrated with business plans. Continuous improvement principles are presented, within the six sigma format. The course will help prepare students for six sigma blackbelt certification. Students can receive credit for only one of the following: RMET-730, CQAS-701, or ISEE-682. (This course is restricted to students in MMSI-MS, MCET/MMSI-BSMS, EMET/MMSI-BSMS, MECA/MMSI-BSMS, RMET/MMSI-BSMS programs.) Lecture 3 (Spring). | ||

| ISEE-682 | Lean Six Sigma Fundamentals |

|

This course presents the philosophy and methods that enable participants to develop quality strategies and drive process improvements. The fundamental elements of Lean Six Sigma are covered along with many problem solving and statistical tools that are valuable in driving process improvements in a broad range of business environments and industries. Successful completion of this course is accompanied by “yellow belt” certification and provides a solid foundation for those who also wish to pursue a “green belt.” (Green belt certification requires completion of an approved project which is beyond the scope of this course). (This course is restricted to degree-seeking graduate students and dual degree BS/MS or BS/ME students in KGCOE.) Lecture 3 (Fall, Spring, Summer). | ||

| STAT-145 | Introduction to Statistics I |

3 |

This course introduces statistical methods of extracting meaning from data, and basic inferential statistics. Topics covered include data and data integrity, exploratory data analysis, data visualization, numeric summary measures, the normal distribution, sampling distributions, confidence intervals, and hypothesis testing. The emphasis of the course is on statistical thinking rather than computation. Statistical software is used. (Prerequisites: Any 100 level MATH course, or NMTH-260 or NMTH-272 or NMTH-275 or (NMTH-250 with a C- or better) or a Math Placement Exam score of at least 35.) Lecture 3 (Fall, Spring, Summer). | ||

| STAT-146 | Introduction to Statistics II |

4 |

This course is an elementary introduction to the topics of regression and analysis of variance. The statistical software package Minitab will be used to reinforce these techniques. The focus of this course is on business applications. This is a general introductory statistics course and is intended for a broad range of programs. (Prerequisites: STAT-145 or equivalent course.) Lecture 6 (Fall, Spring, Summer). | ||

| Choose one of the following: | 3 |

|

| COMM-142 | Introduction to Technical Communication (WI) |

|

This course introduces students to current best practices in written and visual technical communication including writing effective email, short and long technical reports and presentations, developing instructional material, and learning the principles and practices of ethical technical communication. Course activities focus on engineering and scientific technical documents. Lecture 3 (Fall, Spring). | ||

| COMM-221 | Public Relations Writing (WI) |

|

This course covers a variety of forms of writing for public relations, including news releases, newsletters, backgrounders, public service announcements, magazine queries, interviews, coverage memos, media alerts, features, trade press releases, and public presentations. Students will write for a variety of media including print, broadcast, and the web. Lecture 3 (Fall, Spring). | ||

| COMM-253 | Communication (WI) |

|

An introduction to communication contexts and processes emphasizing both conceptual and practical dimensions. Participants engage in public speaking, small group problem solving and leadership, and writing exercises while acquiring theoretical background appropriate to understanding these skills. Lecture 3 (Fall, Spring). | ||

| ENGL-260 | Written Argument (WI) |

|

This course is a rigorous introduction to the formal study of rhetoric. Often defined as the “art of persuasion,” rhetoric helps us understand the complexities of marshaling others to see, believe and act in particular ways. Reading a range of rhetorical theory—from the ancient to the contemporary—students will investigate how language is used to create meaning, construct identity, organize social groups, and produce change. Because argument and persuasion inherently involve ethical questions of power, students will also consider who and what benefits or is marginalized by particular assumptions, claims and practices. The course emphasizes cultural rhetoric and rhetorical genre theory to ask what different types of texts do, what cultural role they play in shaping knowledge, and what ideologies they embody. Students will analyze the rhetoric observed in a range of media—academic research, public communication, digital material, data visualization—and compose arguments, identifying assumptions, misinformation/disinformation, and counter arguments. Students engage with rhetorical theory to pose complex questions about important social issues, consider the discursive requirements of the moment, and write intentionally for a target audience. Lecture 3 (Fall, Spring, Summer). | ||

| SOIS-325 | Business Communication (WI) |

|

This course focuses on the development of communication skills essential to functioning effectively in the business world. Students learn the process of analyzing communication situations and responding to them. Topics include an overview of business communication, writing well, delivering business communications, tools for talking in crucial conversations, oral and interpersonal communication including listening skills, public speaking, cross-cultural communication, communicating in the digital age and teamwork. *Note: This course cannot be taken by students in Saunders College of Business.* (This class is restricted to undergraduate students with at least 2nd year standing. Saunders College of Business students are not permitted to take this course.) Lecture 3 (Fall, Spring). | ||

| Fourth Year | ||

| MCET-210 | Foundations of Non-Metallic Materials |

2 |

This course will cover the process of selecting a best material for a given design application with a focus on polymeric materials. To support this process material families, strengthening mechanisms, and degradation mechanisms and prevention will be studied. The materials selection process will include economic, ecological, and ethical considerations. An emphasis is placed on the interrelationship of structure, process, and properties. This class expands upon concepts presented in MCET-110. (Prerequisites: C- or better in (CHMG-131 or CHMG-141 or CHEM-151) and (MCET-110 and MCET-111) or (NETS-110 and NETS-111) or (MECE-304 or MECE-305 and MECE-306) or equivalent courses.

Corequisite: MCET-211 or equivalent course.) Lecture 2 (Fall, Spring). | ||

| MCET-211 | Characterization of Non-Metallic Materials Lab |

1 |

This course will consist of laboratory experiences which focus on property characterization of the properties of polymeric materials. (Co-requisites: MCET-210 or equivalent course.) Lab 2 (Fall, Spring). | ||

| MECA-335 | Applications of Fluid Power & Heat Transfer |

3 |

This course focuses on fluid power, fluid mechanics, flow mechanisms, heat transfer, and the ideal gas laws in the context of mechatronic and robotic systems. Students learn to design and construct pneumatic and hydraulic circuits and controls. Issues of fluid forces, flow characterization, efficiency, losses are applied to pumps, compressors, accumulators, and control valves. Basics of heat transfer, flow mechanisms, and ideal gas laws are applied to robotic and mechatronic systems Laboratory activities put the theory into practice. The course culminates in a comprehensive project where students design and build an electro-fluid power system to solve a practical problem. (Prerequisites: C- or better in MCET-220 or MECE-103 or CVET-210 or equivalent course.) Lab 1, Lecture 3 (Fall, Spring). | ||

| RMET-420 | Quality Engineering Principles |

3 |

This course is designed to introduce the student to techniques required to maintain and improve quality within manufacturing organizations and the service sector through the use of statistical methodologies. The course covers concepts of quality, quality managements and assurance, product quality, design of quality control chart, statistical process control, and quality improvement through design by considering concept development and implementation. Traditional and modern quality systems will be discussed including the work of such quality gurus like Taguchi, Deming, Juran, and Shewhart. (Prerequisites: STAT-145 or STAT-205 or STAT-251 or MATH-251 or equivalent course.) Lecture 3 (Fall, Spring). | ||

| RMET-499 | RMET Co-op (summer) |

0 |

One semester of experience in a job related to the student's major. Department permission is required. (Prerequisites: ENGT-95 and MCET-150 and MECA-290 and RMET-340 or equivalent courses.) CO OP (Fall, Spring, Summer). | ||

| RMET-565 | RMET Engineering Technology Capstone Project (WI-PR) |

4 |

This is the Engineering Technology Common Capstone Project course where students address open-ended problems. Emphasis is placed on teamwork, the design process, and project management tools addressing project scope, schedule, milestones, deliverables, risk, and cost. The course also focuses on developing oral, written and interpersonal communication skills. In this course, cross-disciplinary student teams develop their proposed mechanism or machine after identifying customer needs, and possible alternative concepts. The mechanism or machine must include sufficiently complex mechanical and electrical subsystems, a control system, and a manufacturing system design. The subsystems of the design must be effectively integrated to achieve proper operation of the mechanism or machine. The final system design must be supported by sound engineering analyses and by engineering designs necessary to build a prototype. The design will be implemented through further analysis, testing, documentation, demonstration, and presentation of a fully functional prototype. This course is intended to be taken as a capstone design experience near the conclusion of the student's program of study. (Prerequisites: RMET-340 and RMET-585 and RMET-420 and RMET-460 or equivalent courses.

Co-requisites: RMET-545 or equivalent course.) Lab 3, Lecture 3 (Fall, Spring). | ||

| STAT-670 | Design of Experiments |

3 |

How to design and analyze experiments, with an emphasis on applications in engineering and the physical sciences. Topics include the role of statistics in scientific experimentation; general principles of design, including randomization, replication, and blocking; replicated and unreplicated two-level factorial designs; two-level fractional-factorial designs; response surface designs. Lecture 3 (Fall, Spring). | ||

General Education – Immersion 1 |

3 | |

MMET Concentration Courses |

6 | |

Open Elective |

4 | |

| Fifth Year | ||

| ACCT-603 | Accounting for Decision Makers |

3 |

A graduate-level introduction to the use of accounting information by decision makers. The focus of the course is on two subject areas: (1) financial reporting concepts/issues and the use of general-purpose financial statements by internal and external decision makers and (2) the development and use of special-purpose financial information intended to assist managers in planning and controlling an organization's activities. Generally accepted accounting principles and issues related to International Financial Reporting Standards are considered while studying the first subject area and ethical issues impacting accounting are considered throughout. (This class is restricted to degree-seeking graduate students or those with permission from instructor.) Lecture 3 (Fall, Spring, Summer). | ||

| Choose one of the following: | 3 |

|

| DECS-744 | Project Management |

|

A study in the principles of project management and the application of various tools and techniques for project planning and control. This course focuses on the leadership role of the project manager, and the roles and responsibilities of the team members. Considerable emphasis is placed on statements of work and work breakdown structures. The course uses a combination of lecture/discussion, group exercises, and case studies. (This class is restricted to degree-seeking graduate students or those with permission from instructor.) Lecture 3 (Fall, Spring). | ||

| PROF-710 | Project Management |

|

This course addresses project management from a multidisciplinary perspective, covering the fundamental nature of and techniques for managing a broad range of projects. Topics cover the Project Management Life Cycle from Planning to Termination. It also addresses the behavioral and quantitative facets of project management, as well as the use of methods, tools and techniques for the initiation, planning, and execution of projects. Introduces the standard framework, processes and knowledge areas of the Project Management Institute. *Note: Bachelors degree or minimum of 5 years of work experience in a project related business environment. Recommended education or work experience in organizational behavior, mathematics and basic accounting. *Note: BUSI-510 may not be substituted for BUSI-710 in a graduate concentration or the advanced certificate in project management. Additionally, a student may not register for and receive credit for both BUSI-510 and BUSI-710, whether taken as an undergraduate or graduate student. (This class is restricted to degree-seeking graduate students or those with permission from instructor.) Lecture 3 (Fall, Spring, Summer). | ||

| Choose one of the following: | 3 |

|

| MFET-788 | MMSI Thesis Planning |

|

MMET Elective Course |

||

| Choose one of the following: | 3 |

|

| RMET-790 | MMSI Thesis |

|

The MMSI thesis is based on thorough literature review and experimental substantiation of a problem, by the candidate, in an appropriate topic. A written proposal has to be defended and authorized by the faculty adviser/committee. The proposal defense is followed by experimental work, a formal written thesis, and oral presentation of findings. The candidate should have completed the requisite courses for the program before enrolling for the thesis. (Prerequisites: RMET-788 or equivalent course.) Thesis 3 (Fall, Spring, Summer). | ||

| RMET-795 | MMSI Comprehensive Exam, plus one (1) MMET Elective |

|

A written comprehensive exam is one of the non-thesis or non-project methodology for completion of the MS-MMSI degree. Students will demonstrate a fundamental knowledge of the theories and foundation principles. This course will require the student to do an independent review of the concepts within the core courses and the chosen concentration area, and will culminate in a comprehensive written examination. The student must receive a passing grade of at least 80 percent to be successful. Students will have one additional opportunity to pass the exam, if their initial attempt results in a failing grade. (Enrollment in this course requires permission from the department offering the course.) Comp Exam 3 (Fall, Spring, Summer). | ||

| RMET-797 | MMSI Capstone Project |

|

This course provides the MMSI graduate students an opportunity to complete their degree requirements by addressing a practical real-world challenge using the knowledge and skills acquired throughout their studies. This course is not only the culmination of a student's course work but also an indicator of the student's ability to use diverse knowledge to provide a tangible solution to a problem. The capstone project topic can be in the areas of product development, manufacturing automation, management system, quality management or electronics packaging. The course requires a comprehensive project report and a final presentation. (Enrollment in this course requires permission from the department offering the course.) Project 3 (Fall, Spring, Summer). | ||

Open Elective |

3 | |

General Education – Immersion 2, 3 |

6 | |

General Education – Elective |

3 | |

MMET Concentration Course |

3 | |

MMET Elective Course |

3 | |

| Total Semester Credit Hours | 154 |

|

Please see General Education Curriculum (GE) for more information.

(WI) Refers to a writing intensive course within the major.

* Please see Wellness Education Requirement for more information. Students completing bachelor's degrees are required to complete two different Wellness courses.

Admissions and Financial Aid

This program is STEM designated when studying on campus and full time.

First-Year Admission

First-year applicants are expected to demonstrate a strong academic background that includes:

- 4 years of English

- 3 years of social studies and/or history

- 3 years of math is required and must include algebra, geometry, and algebra 2/trigonometry. Pre-calculus is preferred.

- 2-3 years of science. Chemistry or physics is required and biology is recommended.

- Technology electives are preferred.

Transfer Admission

Transfer applicants should meet these minimum degree-specific requirements:

- A minimum of college algebra is required. Pre-calculus or calculus is preferred.

- Chemistry or physics is required.

Financial Aid and Scholarships

100% of all incoming first-year and transfer students receive aid.

RIT’s personalized and comprehensive financial aid program includes scholarships, grants, loans, and campus employment programs. When all these are put to work, your actual cost may be much lower than the published estimated cost of attendance.

Learn more about financial aid and scholarships

Accreditation

The BS in robotics and manufacturing engineering technology major is accredited by the Engineering Technology Accreditation Commission of ABET, https://www.abet.org, under the General Criteria, Program Criteria for Instrumentation and Control Systems Engineering Technology and Similarly Named Programs, and Program Criteria the Manufacturing Engineering Technology and Similarly Named Programs.

Visit the college’s accreditation page for information on enrollment and graduation data, program educational objectives, and student outcomes.

Resources

Access Resources for students including academic advisors, student clubs and organizations, documents, technical information and support, and software help.

Related News

-

May 2, 2024

![Orlando Ortiz sits for a headshot against a gray background wearing a gray plaid suit.]()

Ortiz named Alumni Association president