All Seeing Eye

The All-Seeing Eye is an Engineering House project started from some members' interests in animatronics and fascination with horror. The goal of this project is to combine engineering and art to create a mildly terrifying animatronic that explores computer vision, motor control systems, atypical mechanisms, cosmetic materials application, audience-focused decision making, and much more. The idea for this project was formed in the summer of 2021, and design work started during the following fall semester. The eye is articulated using four MG996R servos connected to rigid rods on universal joints. Inside the pupil of this eyeball is an 8MP 1080P camera with 170° fisheye lens. This camera is connected to a computer that is running computer vision software (based on the open-source OpenCV library), which detects the locations of people in its vision. This is then used to communicate with an ESP32 that controls the servos to look at the detected face and follow them until they go out of range or another person is detected. The eyeball is 3D printed and painted to resemble a real human eye. The body is a continuum robot mechanism, also known as a tentacle mechanism in the special effects industry. This consists of wooden discs attached to an incompressible, flexible core made from braided drain hose. Each disc has holes with sleeve bearings for the controlling cables to pass through. This is a two-stage tentacle mechanism, meaning that the top half articulates independently of the bottom half. The independence is achieved by having the upper cables pass through the bottom discs in bowden tubes (cable sheathing), which keep the length of the second-stage cables within the first stage constant and prevents interference between the two stages. The cables are actuated using pulleys on NEMA 23 Stepper motors with a 15:1 gearbox. These motors can theoretically hold over 50lbs on a single cable with their high torque gearboxes. The Arduino MEGA also controls these motors by sending driving signals to DM542T stepper motor drivers. Each stage appears to have four cables controlling it, but in reality there are just two cables controlling the mechanism, while the two opposing the control cables are attached to constant force springs to keep the system in tension. This also deals with the problem of one side requiring just as much slack in the cable as is taking from the other side. Because there are two stages, there are four stepper motors and cables total. The base of this animatronic (which houses the stepper motors, controlling circuitry, power supplies, and computer) is an old AV rack that has been repurposed for this project. This makes the animatronic easy to move and contains all of its components to one cart. The skin of the animatronic is made from Smooth-On Dragon Skin FX Pro silicone. This is an industry-standard silicone used for animatronic and mold-making purposes.

The tentacle mechanism loosely curled up

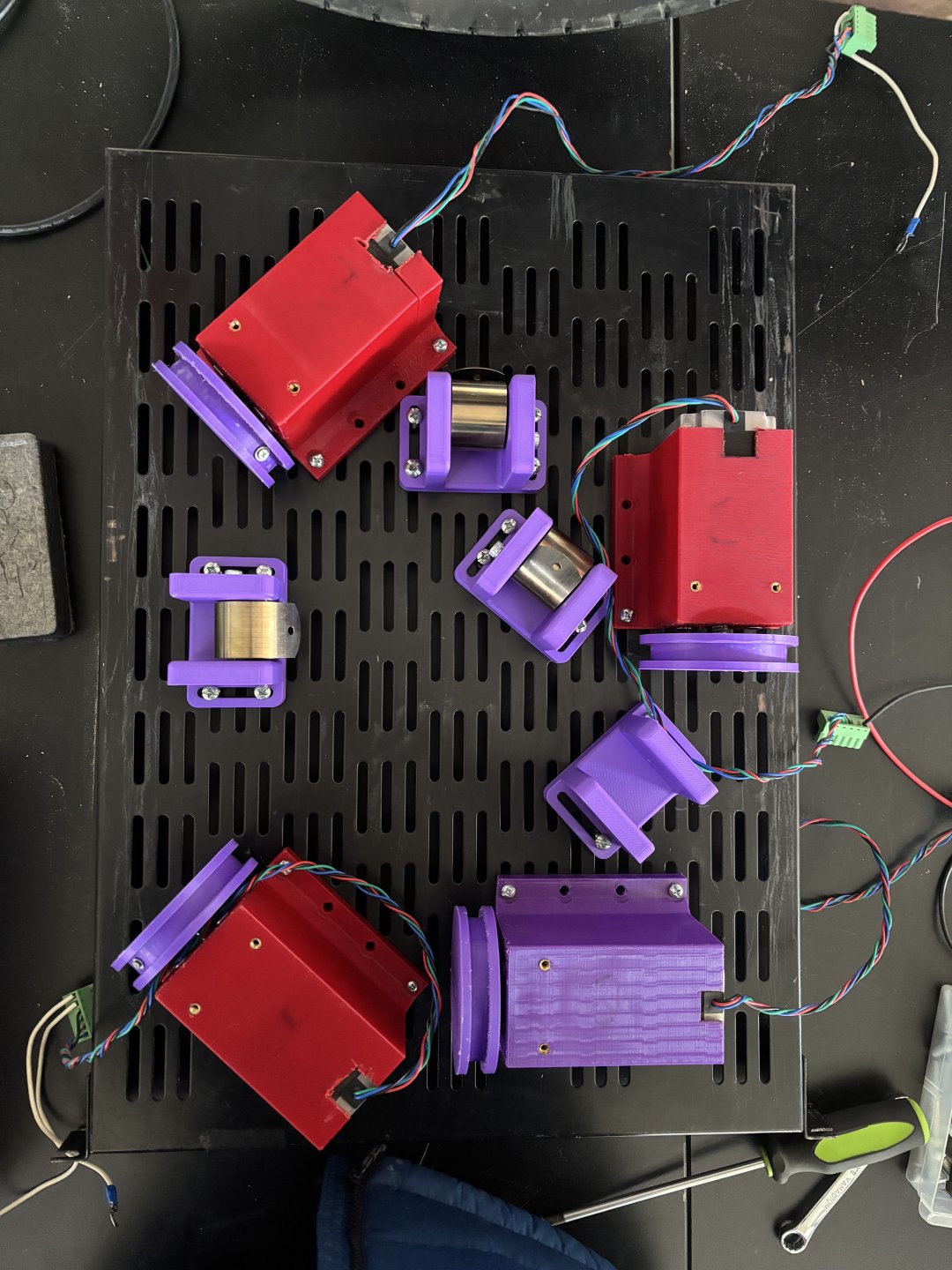

Internals of All Seeing Eye mechanisms

Motors that control the tentacle mechanism

The tentacle mechanism pinned in a position

Topics

Exhibitor

Adam Schultzer

Ava Curby

Eddie Satkowski

Nat Kleit

Sam Lipkin

Nat Krah

David Martin

Alex Polo

ajr8765

Organization

Engineering House

Thank you to all of our sponsors!