Dual Charged Forced Induction Kit for Passenger Automobiles

Location

Outside (OUT/000) - Unity Quad

A Dual Forced Induction System is an engine performance accessory that utilizes a Supercharger, for low-end power boost, and a Turbocharger, for high-end power boost, to allow additional power throughout the engine’s entire operating range. The Supercharger forces air into the engine using the engine's own rotation via the Serpentine belt. The Turbocharger forces air into the engine via a small rotating turbine powered by the engine's own exhaust gas. Individual Supercharger and Turbocharger systems currently exist for multiple engines, but there are no widely available systems that include both to capitalize on the benefits of each. This project included predicting the prototype system's performance via team developed computer models, conducting CFD simulations of an engine system using current 3D engine models with different Turbocharger sizes, performing heat simulation of the system during operation, automating the overall system design process, and demonstrating the operational performance capabilities of a prototype Dual Forced Induction System by installing it onto a current engine platform (Honda K24). The resulting prototype system is able to be contained within the vehicle’s original engine area, provide a minimum power (WHP) requirement, be able to be installed by mechanics and technically inclined enthusiasts (user friendly), and be manufactured/composed of primarily commercially available components for ease of maintenance and reduce the price to the end-user. A visitor of this exhibit will be able to to view the prototype Dual Forced Induction System installed on a physical car (2004 Acura RSX w/ Honda K24 engine), see videos of the car driving and performing with the system, and see the resulting performance data of the prototype system.

The team started the project by moving the engine, parts, equipment, and tools into our MSD supplied workspace in early Fall.

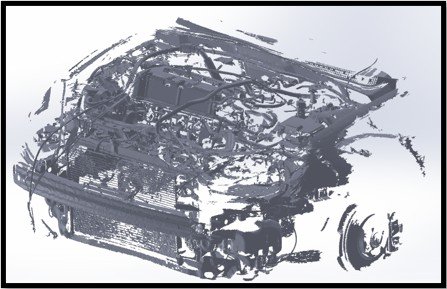

3D Scan of the car's engine bay and stock engine using a scanner available to student at The SHED.

The OEM engine bay setup for the 2004 Acura RSX. This is the starting point for the whole project.

Reassembling the engine head while upgrading and rebuilding internal engine components. Here, the team is "lapping" the valves.

Removing the existing stock engine in preparation for installing the upgraded and rebuilt engine. Removing the engine took 4 hours, but installing the rebuilt engine took twice as long!

The team removing engine components and accessories in preparation to swap the engine.

Before installing the entire Dual Forced Induction Kit, the team mocked-up the Supercharger with its custom mounts and pipe adaptor flange to test fitment.

Location

Outside (OUT/000) - Unity Quad

Topics

Exhibitor

Ryan Marino

Aly Troidl

Jack Snyder

Alex Schneider

Zach Claus

Steven Miller

Advisor(s)

Mark Minunni (MSD Guide)

Organization

This is a MSD, student-led project. We do not have an affiliated client or financial sponsor.

Thank you to all of our sponsors!