Fab Lab’s classic car project drives 3D scanning exploration

Jackson Burns Bulmer '27

Tiree Walker, manager of the College of Art and Design's Fab Lab, is using 3D scanning technologies to efficiently identify mechanical and physical imperfections on a 1978 MG Midget. Tracking dots were placed all over the classic car to execute the 3D scans.

The Fab Lab is revving its creative engine.

A portion of the College of Art and Design’s digital fabrication center has been temporarily transformed into a part car garage and part technology testing ground.

The Fab Lab is housing a 1978 MG Midget, a lightweight classic sports car that is activating explorations in large-scale 3D scanning.

Jackson Burns Bulmer '27

Walker purchased the classic car in fall 2023.

Tiree Walker, instructional support specialist and manager of the Fab Lab, purchased the car in the fall. The acquisition was twofold: he always wanted to own a classic car, and he observed an opportunity to leverage the vehicle to advance the applications and implementations of the Fab Lab’s digital fabrication equipment.

“I realized I could incorporate it into my job as a way to explore my knowledge and open everyone else’s minds to the different technologies that we have available,” said Walker, a 2021 industrial design alumnus. “It’s awesome, and some people just don’t know what you can do with it.”

Jackson Burns Bulmer '27

The classic car is being housed in a space adjacent to the College of Art and Design's Fab Lab, located on the second floor of Booth Hall.

The mini two-seater was rolled through a sliding window and into a room behind the main Fab Lab area in service of Walker’s research. He and a student employee team plastered the car with small tracking dots and 3D scanned the car to easily pinpoint areas in need of modification or repair, whether mechanical or physical imperfections.

The process of 3D scanning an object involves collecting data of its shape and appearance to be used for constructing digital 3D models. Using these technologies provides a more efficient, comprehensive overview of the car than the naked eye can accomplish.

“One of the great things about 3D scanning is, instead of having to drag yourself underneath the car to keep looking at the same thing, you can have it on the computer pulled up, and you can zoom in and out fluently to pinpoint these problem areas,” Walker said.

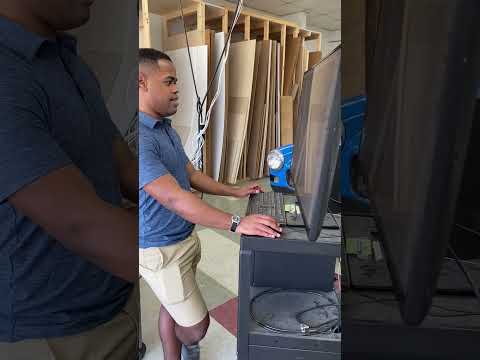

Jackson Burns Bulmer '27

Walker operates the computer-aided software he deployed for this research.

Walker is also training himself on Autodesk Alias, computer-aided industrial design software primarily deployed in the automotive industry. He plans to use it to investigate the possibility of manipulating the 3D scans to make replacement or custom parts.

“There are ergonomics and a design language already in the car that you can scan and reproduce newer components that flow into the design,” Walker said. “It’s also an opportunity to use the Fab Lab to showcase how you can take 3D scan data from a real-world object and then reproduce it using a number of manufacturing processes like CNC (computer numerical control) and 3D printing in order to get replica parts or even modified design parts.”

For this research, Walker used available equipment and technologies in the Fab Lab in addition to borrowing a state-of-the-art 3D scanner from the SHED.

“The biggest thing for me is trying to use this to show students and faculty all the capabilities of the Fab Lab and some of the other resources on campus to inspire them to push projects they’re working on,” Walker said.

Jackson Burns Bulmer '27

Walker will continue his research throughout the summer.