Projects

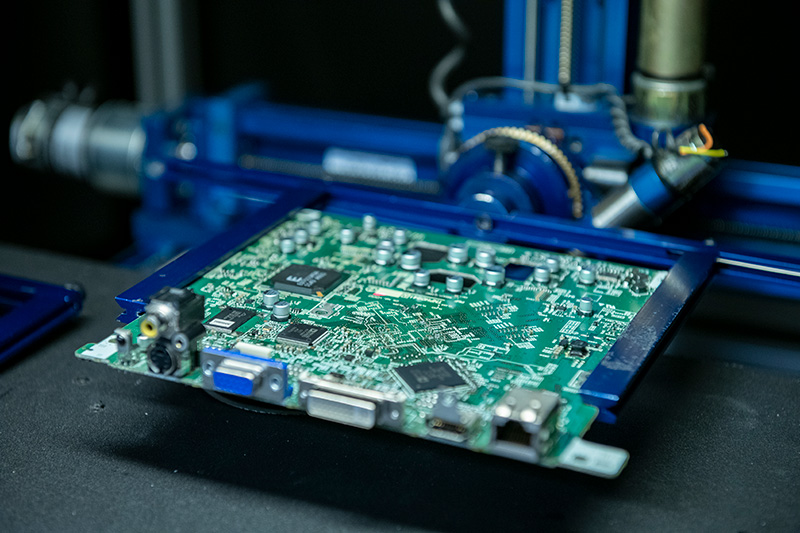

Prototype Board Assembly

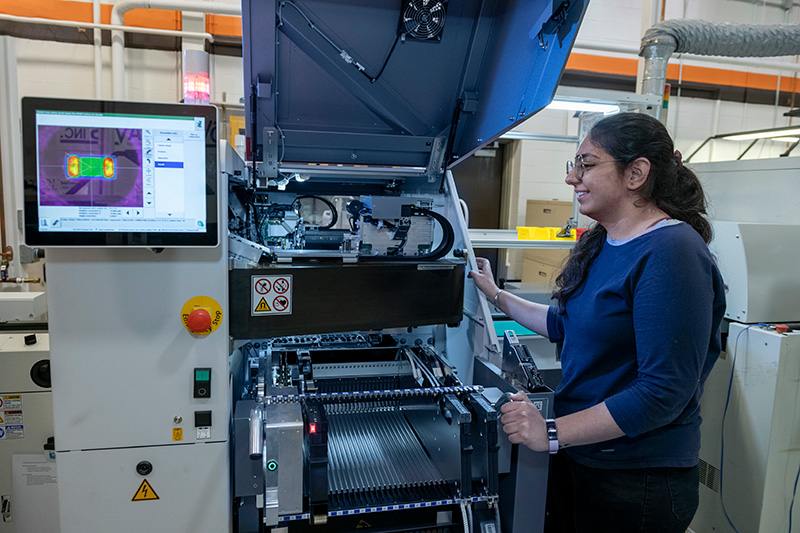

CEMA is equipped with state-of-the-art facilities capable of producing prototype assemblies and providing board design, manufacturing, inspection, testing and rework services.

- Assemble short run prototype PCB assemblies for customers

- Test and prove assembly process for customers, for new product introduction

- Convert manually built prototypes to a fully automated assembly process

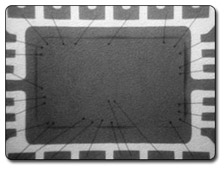

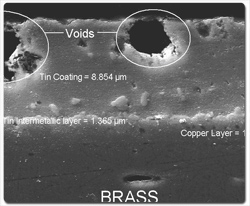

Electronic Failure Analysis

- Analytical evaluation of PCB Assemblies

- Cross-sectioning, specimen preparation and evaluation

- Scanning Electron Microscopy (SEM)

- Vibration/durability, shock testing

- Temperature and humidity testing

Process Evaluation

CEMA can help evaluate and optimize assembly processes to maximize productivity. Process evaluation can include board design, paste and stencil technologies, print parameters, dispensing techniques, oven profiles, etc. CEMA can also help with process development, new product introduction and prototype build.

Materials Evaluation

CEMA offers applied research and evaluation of materials including substrates, solder pastes, adhesives, underfills and conductive epoxies. Key players such as material manufacturers, substrate and component suppliers, and EMS providers need to understand the impact of materials, as the industry develops new packaging technologies. CEMA can provide comprehensive support to industry for material evaluation and characterization.

- Stencils: Materials, thickness, printability, surface finish, aperture wall finish, stencil coatings

- Board: Design, layouts, finish, DFM/DFA

- Adhesives: Conductive, encapsulation, underfill, dispense/print, curing, characterization

- Squeegees: Materials, types, printability, life, applications

- Solder Paste: Types, characterization

- Process: Print parameter specification, machine setup, profile generation, machine program generation, rework & repair

Consultation on Process Implementation

CEMA can help evaluate and optimize assembly processes to maximize productivity. Process evaluation can include board design, paste and stencil technologies, print parameters, dispensing techniques, oven profiles, etc. CEMA can also help with process development, new product introduction and prototype build.

- Assist in establishing SMT assembly facility

- Assist in establishing SMT assembly lines & and plant layout

- Assist in solving startup or ongoing production problems

- Identifying training needs and production methods

- SMT Facility Audit

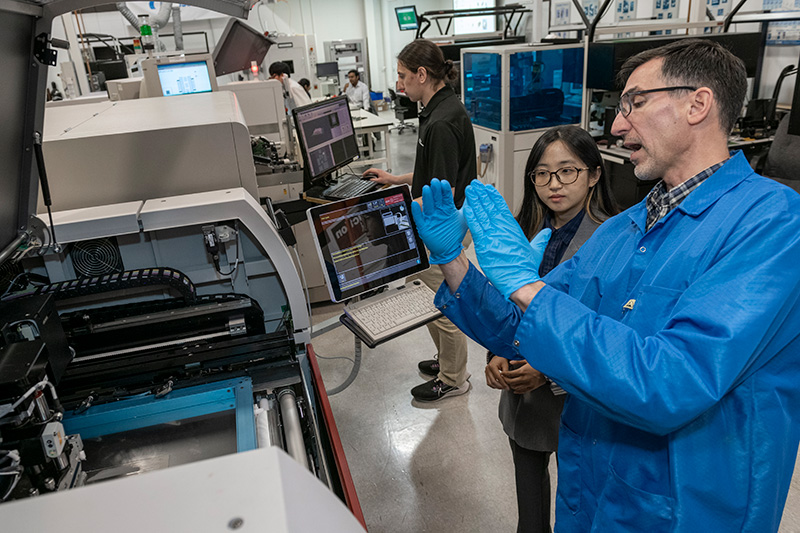

Equipment Showcasing, Evaluation, and Testing

CEMA provides beta testing, evaluation and process capability analysis for electronics packaging equipment. From life cycle testing to ergonomics and functionality evaluation, equipment manufacturers can get an objective evaluation of the impact of their equipment technology on the electronics/optoelectronics assembly process.

- Hosting equipment manufacturers to test their equipment in-line or independently

- Train equipment manufacturer's customers on their equipment

- Trial assembly line implementation and testing

- Beta testing site for equipment hardware & software

- Showcase for manufacturer's equipment