Ezrobot Revolution JD Humanoid

Ezrobot Revolution JD Humanoid. JD is a fully functional humanoid robot kit, built with EZ-bits. This humanoid design is fun and educational! JD can interact with human tools and environments for experimental purposes. This humanoid boasts 16 degrees of freedom with metal gear heavy-duty servo motors! The camera in JD's head can be used for visual tracking and recognition – color, motion, glyphs, QR codes, and faces. Each eye has 9 RGB LEDs, which can be programmed for a variety of expressions. The included EZ-Builder Software makes it easy to create animations to customize movements.

Dobot Magician Educational

DOBOT Magician is a multifunctional desktop robotic arm for practical training education. Installed with different end-tools, DOBOT Magician can realize interesting functions such as 3D printing, laser engraving, pen, suction cup, and gripper. It supports secondary development by 13 extensible interfaces and over 20 programming languages, which really makes your creativity and imagination increase without any limitation. In recognition of its excellent performance in hardware design and software application

Dobot Mini Conveyor Belt

A conveyor belt with adjustable speed. Equipped with optical switch and color sensor. Combined with the DOBOT Magician a very realistic simulated production line. It is really applicable in manufacturing processes. The Conveyor Kit for DOBOT Magician makes it possible to own a complete simulated production line. The powerful and programmable DOBOT Magician, when combined with the conveyor belt of adjustable speed, distance, and color sensor, is the ideal and perfect tool for you to create a highly effective simulated production line, or even to apply to actual factory application scenarios

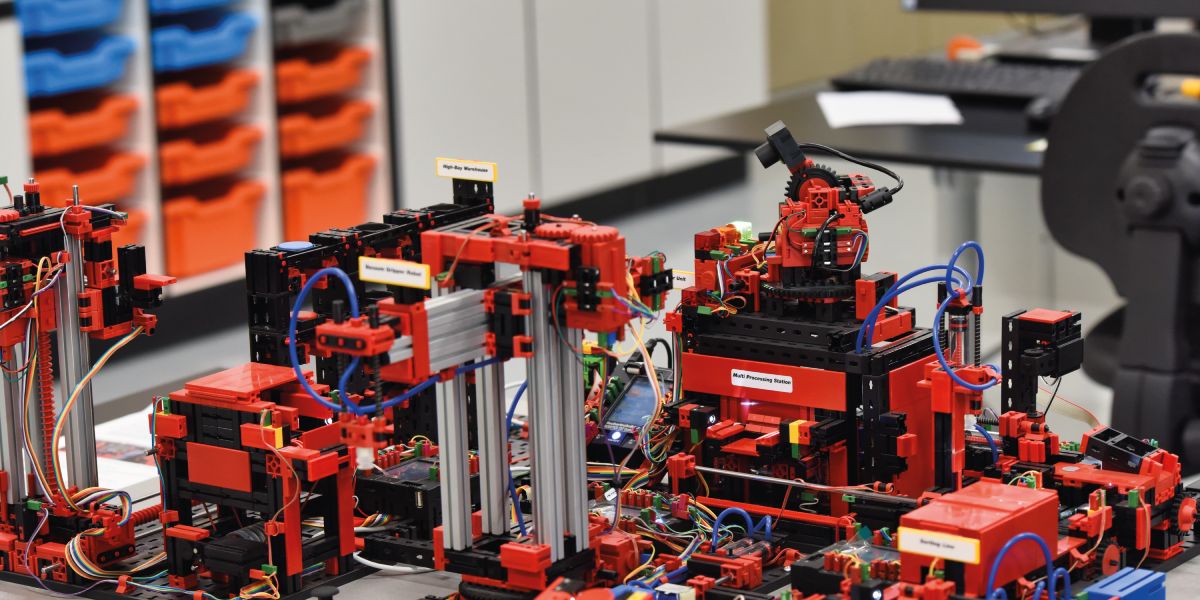

The Training Factory

The Training factory Industry 4.0 learning environment is used for learning and understanding industry 4.0 applications in vocational schools and training as well as for research, teaching, and development at universities. The simulation depicts the ordering process, the production process, and the delivery process in digitized and networked process steps.

Dobot M1

This is a cost-effective intelligent robotic arm for the light industry. With high precision, wide working range, complete functions, and secondary development, it provides users more ways to use. M1 can realize multiple functions of assembly line work such as soldering, visual recognition, and PCB plug-in, helping to construct the intelligent industrial system.

Educational Primary Solution (Makeblock)

STEAM Education Primary Solution provides resources that help university students set up their STEAM labs and organize robotics competitions. It includes 26 boxes of components, 8 storage trays, and 6 packs of runners and clips compatible with storage shelves. The solution can work with MakerSpace series-based primary courses, making it a perfect setup for classroom teaching (for a class size of 2-8 students) and maker education activities (for 8 - 16 students involved).

Automatic Storage and Retrieval Systems

ASRS is a part of the HYTECH CIM / FMS system, Entire system is controlled through PLC, HMI, and SCADA. Every axis is powered by AC Servo Motors. The accuracy achieved is 0.020mm. No of Cells: 36. Input Supply: Three Phase / Single Phase. OPC UA connectivity with industry 4.0.